A warm garage is a dream of any motorist. At one time I was happy as a child when I managed to get a good, as it seemed to me at that time, metal garage. But it soon became clear that in the off-season it dries, and in winter it protects only from the wind. Therefore, quite quickly the question arose of warming. I decided to devote this material to how to insulate a metal garage with my own hands. In it, I will tell about my own experience and tell you what advice different experts gave me.

Classic iron garage.

According to SNiP 21.02-99, for comfortable storage of cars and trucks and starting the engine without preliminary preparation, the temperature in the box (garage) should not fall below + 5 ° C, and this should be repelled.

What insulation is better to take

Naturally, the warming of an unheated metal garage in any normal host begins with the choice of material. And if earlier it was mainly just polystyrene, now the market provides many options.

All of them can be conditionally divided into 4 directions:

- Plate materials of medium and high strength,

- Soft fibrous,

- Foam,

- Liquid heaters.

Comments 47

I did it myself, glued all the metal with porous 3mm plastic onto the mounting foam, overlaid the foamed foil with 5mm stapler over the stapler, glued the joints with aluminum tape. There is a 2 kW gun, it warms up from 0 to +10 in an hour and a half. The garage is about the same 3.5 by 6. I did it from what it was. Spent only 5 cylinders of mounting foam.

Oh yes. And all the cracks at the gate were sealed, otherwise siphon.

Expanded polystyrene + thin rail + self-tapping screws.

From the outside, you turn holes in the metal, through them you fix the wooden rail with screws. To the rail, polystyrene foam (50-ku, less - nonsense), irregularities and inconsistencies - to foam, seams - to seal with ordinary tape.

The most budget option. Well, if you reduce the cost, it’s polystyrene, but a mouse ... it’s like an apartment building to them.

I pasted the garage with polystyrene foam on the mounting foam. The task was to make a sealed cocoon, i.e. all joints are good to foam. During gluing on the non-glued pieces of the roof, condensation formed which dripped. Condensation formed after the heated air began to cool at night. After everything has been carefully glued, condensation does not form. On thermal calculators there is no dew point at 50mm polystyrene foam. I look forward to frosts and winters, I will watch further.

And I’ll add. The walls are crooked. In some places, the eps didn't touch the metal wall of the garage, much less the roof. The main thing was to prevent the warm air of the garage from reaching the metal. And most importantly, the EPS boards are between them qualitatively foamed. In a couple of places, condensation still dripped from the roof - it’s finished and now everything is ok.

what thickness did eps use?

Better Penoplex 100.

With a margin.

Please note that in penoplex ants are happy to equip anthills. Somewhere on the drive there was even a video, you go into the garage, and in it life is still rustling ...

It all depends on what you want - to get a Kunz camera, both foam and Penoplex will do. And if a dry and warm garage, without the risk of getting burned, then mineral wool in the frame.

Fifty years of iron garages have stood on damp ground. High water annually. Not rotted yet. What are you afraid of ?

I missed the walls with liquid bitumen. Slightly dried up, and pasted polystyrene 40ku. He did it with gaps, then he replaced them. Aligned with a knife. Then he painted over with paint on an oil-based basis (I just had a lot of it) to clog micropores.

Now I bought cheap aprons for the kitchen in the store, I'll stick it on top.

I'm not afraid, I just want to do the right thing))

Insulation from the inside. Profiles for cardboard, hydro-wind protection, cotton wool techno-nikol, vapor and moisture insulation, OSB. Walls 200 ... 250 mm, ceiling 100 mm, gate 80 mm (gate insulated with foam).

Floors 2/3 log / wood / cotton, 1/3 concrete (above the basement). I recommend doing the entire floor on the lags.

Compulsory ventilation, a heating device - AKOG-4, with a coaxial chimney, 40 l of gas is enough for 20 days of continuous heating, at -20 on the street +16 in the garage per unit (a total of 7 power positions).

And let well-read wiseacres not tweet about the dew point.

I have not tried it, just as an assumption. There is a sprayed polyurethane foam insulation in cans. If the adhesion with metal is normal, then there will be no dew under it. Until it has dried, it is possible to glue a sheet of extruded polystyrene foam. Without it, the spraying surface will be uneven, not beautiful.

The coefficient of thermal conductivity of polystyrene foam is 0.036-0.042, depending on the thickness, that is, between 15 and 50 there will be something like 0.006-0.008 (pointed to the eye, but I think the idea will be clear), I would just take the one that is more convenient to work with. When decorating, try to carefully close all the cracks, joints, etc. so that as little warm air as possible touches the iron.

To remove the dew point from the garage, it is necessary to insulate the outside. Do not insulate inside, the dew point will be inside.

and so what will it be inside?

don't let humid air and poher where this point is.

Iron garage, drown a couple of times a week, how not to let humid air in there?

I opened the gate for plowing, while you call in and get the garage. And ventilation, without good ventilation in the iron garage, the car rots be healthy. No membranes will help. And membranes do not drain the air.

you confuse warm and soft.

outdoor air do not care.

it is forbidden to let warm air from the guard to the place where dew may appear, that is, into the insulation.

For this, a membrane is made over the insulation that does not allow internal air to pass into the insulation.

if the membrane is hermetically sealed, you can safely forget about the dew point in the insulation

and given that the garage is not constantly heated but by raids, the insulation is only from the inside.

You are confusing something, what kind of membrane for polystyrene foam, it does not absorb moisture and so on. The warm air from warming up and from the hot car will then cool and the dew point will shift for the heater to the iron of the garage. And if you insulate the outside, and the dew point will be outside.

oooo everything. exit the dialogue.

Learn the subject of discussion.

Once a Finnish-built steamboat written off on nails caught my eye, I drew attention to thermal insulation. A 50 mm thick cork was glued to the iron bulkhead with something black, then a layer of black paper similar to the base of roofing felt, then a cloth like batting, then a grooved pine lath and finally 10 mm thick plywood. Everything was fitted very carefully, the mosquito of the nose will not tarnish.

a very topical issue, I put a metal garage from scratch, and I also think how and what to insulate! Express your opinions about the option (on the inside of the walls):

- vapor barrier on metal walls

- stone (mineral?) Cotton wool

- vapor barrier

- OSB.

iron vapor barrier is needed only if you make a ventilated gap, and then you need wind protection and not vapor barrier.

OSB, although it absorbs moisture poorly, turns black over time.

I'm afraid that condensation will inevitably form on the walls of the garage and will wet the insulation

Do you know how to insulate roofs from professional flooring?

corrugated board, ventilation gap, wind protection, insulation, vapor barrier membrane clearance finish.

eps better holds heat in theory, in practice it is not noticeable, and of course 20 mm can not be compared with polystyrene 50 mm

however, if you take polystyrene for construction, it, unlike eps, does not burn.

and the question arises fuck epps in the garage?

if the garage does not warm up all the time, it is possible to take polystyrene and thinner.

if I were warming, then I would take psb-s (25-35) with a thickness of 30 and cover it with a professional sheet from the outside.

it will turn out a thin insulation, a warm house, while you can safely cook it and cut it with a grinder, even though you don't have to paint my walls with a Karcher, it’s always light (if you take light) is not afraid of condensation (if it happens)

there will never be mold and fungus, and if it is, it will simply be washed off with water and that's it.

At the expense of a professional sheet, a great idea!

this is not an idea, this is the son of difficult mistakes.

over the years I came to this.

eps better holds heat in theory, in practice it is not noticeable, and of course 20 mm can not be compared with polystyrene 50 mm

however, if you take polystyrene for construction, it, unlike eps, does not burn.

and the question arises fuck epps in the garage?

if the garage does not warm up all the time, it is possible to take polystyrene and thinner.

if I were warming, then I would take psb-s (25-35) with a thickness of 30 and cover it with a professional sheet from the outside.

it will turn out a thin insulation, a warm house, while you can safely cook it and cut it with a grinder, even though you don't have to paint my walls with a Karcher, it’s always light (if you take light) is not afraid of condensation (if it happens)

there will never be mold and fungus, and if it is, it will simply be washed off with water and that's it.

Penoplex was simple, so it was put on the roof, and the walls lean more toward 50ke polystyrene. I wanted to glue the polystyrene to the metal, but on a forum I read that it is necessary to roll the isolon tightly on the metal so that there is no air, and then the polystyrene and everything else. How to do better?

Isolon? gee.

if you are very afraid that the iron will begin to rot (although if you do it normally it won’t happen)

then you don’t need to glue anything on the iron, just a medlu iron and insulation is made ventilation gap connected to the street.

I wouldn’t soar my brain with this garbage, I would stick polystyrene to the iron. if you play it safe, you can put a vapor barrier between the foam and the finish. but the foam itself does not allow moisture to the metal.

the metal rots from condensation where it’s shitty, and the internal air quietly penetrates to iron.

It's just that the metal at the garage is not perfectly flat, not a lot of a wave, so it will not work perfectly tightly and in some places there will be an air gap. But as I understand it, it's not scary if you foam seams and other gaps

if the metal is walking, then no stumps will appear, in this case, it is necessary to lay a vapor barrier membrane between the finish and the filler, impermeable.

if the metal is uneven and does not walk, apply the polynor and press it with foam

metal does not walk, just the sheets themselves are crooked. Polinor is glue, as I understand it?

This is a sprayed thermal insulation, well, like foam in a spray can. only it is sprayed with a thin layer.

Thanks for the detailed answer))

It's just that the metal at the garage is not perfectly flat, not a lot of a wave, so it will not work perfectly tightly and in some places there will be an air gap. But as I understand it, it's not scary if you foam seams and other gaps

There is glue mastic butumast for polystyrene foam. Iron protects against moisture and as a glue for PPS.

Isolon? gee.

if you are very afraid that the iron will begin to rot (although if you do it normally it won’t happen)

then you don’t need to glue anything on the iron, just a medlu iron and insulation is made ventilation gap connected to the street.

I wouldn’t soar my brain with this garbage, I would stick polystyrene to the iron. if you play it safe, you can put a vapor barrier between the foam and the finish. but the foam itself does not allow moisture to the metal.

the metal rots from condensation where it’s shitty, and the internal air quietly penetrates to iron.

Do I need to insulate a metal garage

The structure of the metal profile and galvanized sheet steel has the property of quickly heating up and transferring heat to the environment. Therefore, in hot weather, it’s stuffy in the garage, and in winter the car freezes. As a result, vehicle maintenance is accompanied by tangible discomfort.

With temperature differences, condensation forms inside the structure and on the surface of the car. Moisture has a destructive effect on the anti-corrosion coating. This fact leads to the appearance of rust on the metal.

Metal walls without corrosion protection with cheese indoors quickly rust

Metal walls without corrosion protection with cheese indoors quickly rust

According to SNiP 21.02-99, an extremely low temperature indicator is considered to be +5 degrees Celsius. This condition can only be achieved by thermal insulation of the walls and ceiling of the garage. The event will also contribute to the elimination of overheating indoors during the summer.

Ways of warming a metal garage

It is possible to carry out insulation of a garage made of metal inside or outside. If the structure is an autonomous building, then the priority option will be to carry out work from the front side. Often the room is located inside the complex. In this case, it is necessary to have insulation materials indoors, from the inside.

Insulation of a metal garage outside

For external insulation materials are selected in accordance with the selected finish. If plastering is implied, then it is better to stay on hard boards. These include expanded polystyrene. Mineral wool and polyurethane foam can also be used for cladding or brickwork from the class of frost-resistant materials.

As an alternative, manufacturers offer ready-made decorative sheets with insulation. These include hard plates, to which glued corrugated board, clinker tiles or plastic panels are glued. They can be mounted using a special solution, polyurethane foam or lathing.

Insulation from the outside is completed by coloring

Insulation from the outside is completed by coloring

Less commonly, a brick is used to warm a metal garage. This finishing material independently copes with the preservation of heat inside in conditions of -15 degrees Celsius without wind. In other cases, between the masonry and the metal base, additional thermal insulation is fixed, an air gap is arranged.

Insulation of the metal garage from the inside

The interior space of the garage is often exploited as a workshop, a place for storing tools, things. That is, racks, a workplace, tanks can be located around the perimeter. This helps to reduce the area for placing the car.

Insulation of metal walls, protection of insulating cloth, decorative finish leads to a reduction in the area of the garage. Therefore, when choosing materials, their thickness is taken into account. The thin-layer option is polyurethane foam and extruded polystyrene foam.

Polyurethane foam dries relatively quickly, the layer can be 5-6 cm

Polyurethane foam dries relatively quickly, the layer can be 5-6 cm

The better to insulate a metal garage

Garages are rarely heated, therefore, among the main criteria for choosing a heater is a low coefficient of thermal conductivity and moisture absorption, resistance to temperature extremes. Manufacturers present products in a hard, soft, foamy and liquid state. For a metal garage, the following options are relevant:

- Polyfoam and extruded polystyrene foam. Outside, the garage can be insulated with technical stoves, inside only household ones. The material practically does not absorb moisture, lightweight, easy to cut and assemble. For fixing, additional funds can not be used in the organization of the crate. Among the shortcomings note combustibility, fear of solvents and sunlight. The service life is 10-30 years, depending on the composition, production technology. The thickness depends on the density, that is, it is better to lay foam foam inside the building.

- Mineral wool is not resistant to moisture, breathes well and does not allow heat to pass through well. Metal creates an airtight barrier to vapor and air. As a result of the use of fibrous webs, there is a high risk of condensation, which significantly reduces the thermal insulation properties of the material. To eliminate this, you will have to increase the cost of protective equipment. Regarding water absorption and durability for a garage, it is better to choose hard slabs of stone wool.The declared service life exceeds the figure of 25-30 years.

- Penoizol and polyurethane foam are similar in their properties to polystyrene foam and polystyrene foam. The difference lies in a thinner sprayed layer, seamless coating and a life of more than 50 years. The disadvantages of warming an iron garage with penoizol and similar materials include the high cost and the need for special equipment. It is expensive, it requires skills to work. It is worth noting the high consumption. For example, to process the gate you will need 5-7 cylinders.

An alternative to fibrous webs and foams is a thin-coat thermal insulation paint. Manufacturers claim that 1 mm corresponds to 50 mm of mineral wool. That is, 2 layers are enough for the middle strip, and 3-4 mm for the north. Of the minuses, a high total price and high consumption (about 1 l / sq. M) are noted. The declared service life outside is 10-15 years. The composition is applied to the metal by means of a brush with artificial bristles of medium hardness.

How to prepare a metal garage for insulation

The metal base is subject to corrosion. Rusty coating contributes to peeling of glued insulation, the destruction of walls, ceilings, decoration materials. Therefore, to insulate the garage from a metal profile with your own hands, regardless of the chosen thermal insulation, is necessary only after preparing the surface to be treated.

To prevent the formation of rust, manufacturers offer a variety of film-forming agents with deep penetration with anti-corrosion additives. Preparation of the base is to ensure maximum adhesion between the metal and coatings. The process is as follows:

- mechanically eliminate pockets of corrosion, protruding elements and the old coating, dirt deposits,

- the entire metal surface is ground to organize the roughness,

- the warmed base is degreased, cleaned of dust.

Before applying coatings, polyurethane foam or adhesive solution for insulation, a primer is applied. The choice of paint, varnish and impregnation should be based on operating conditions. These include a metal base, internal or external use, temperature extremes, moisture resistance.

How to warm a metal garage

Thermal insulation in a garage made of metal is mounted by means of adhesive solution, special fasteners, battens, sprayed or applied with a brush. Options with foam, liquids and solutions require additional priming of the prepared surface. When choosing, take into account operating conditions: temperature differences with humidity, the nature of the base and finish. In other cases, you need to assemble a crate or frame. It may be necessary to drill technological holes.

It looks like a wooden crate for a tile or roll insulation

It looks like a wooden crate for a tile or roll insulation

Insulation of the iron garage with foam

Expanded polystyrene is relevant for the treatment of smooth and even metal walls, ceilings to prevent the formation of voids. They can cause peeling of the insulation, a place of accumulation of condensate.

In order to save money, it is better to fix heat-insulating cloths on special glue, foam or liquid nails. If there is a laying in the grooves of the crate, then a gap of about 10-15 mm must be observed between the profile or bar and the foam. All joints are filled with low expansion foam to prevent sheet deformation.

Insulation of a metal garage with polyurethane foam

The heat-insulating foam in the garage is sprayed of metal after installing the lathing. It is needed so that it can be further finished with trim materials. According to the installation technology, the base with the frame must be dry, and the ambient temperature more than +10 degrees Celsius. After the working mass has dried, the excess is removed with a construction knife.

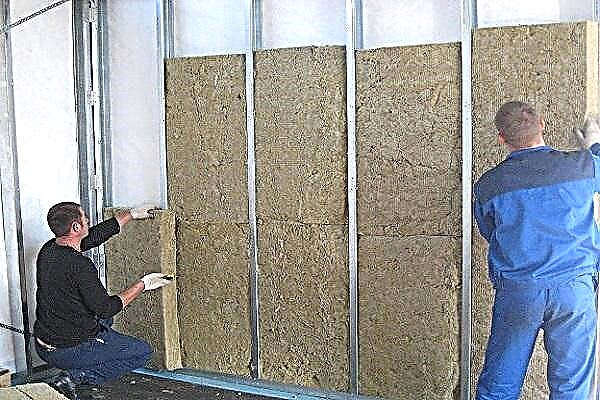

Insulation of a metal garage with mineral wool

The lath for fibrous webs is attached to the frame of a wooden beam or metal profile. As the base under them, use frame racks with guides, a metal profile of the structure. Screws are screwed in with an interval of 20-30 cm. The grooves for the insulation for the metal garage are formed in accordance with the parameters of the heat-insulating sheets and plates, it is only necessary to reduce the width with a height of 2 cm around the perimeter. This will result in a snug fit of the mineral wool to the elements of the supporting structure.

Moisture-absorbing material must be protected from vapors. To do this, install waterproofing from the side of the metal base. Before decorative finishing, a vapor-proof fabric is laid. It is better to use membrane material for these purposes. The edges are lapped by 10-15 cm and sealed with double-sided tape. For fixing use adhesive tape or building brackets with intermediate rails.

If no decorative finishes follow, the vapor barrier should be resistant to chemicals

If no decorative finishes follow, the vapor barrier should be resistant to chemicals

Professional Tips

It is possible to reduce the thickness of expanded polystyrene with internal insulation of the garage by means of isolon. Foamed polyethylene with a foil coating is glued on top of a sheet of foam indoors. The disadvantage of such insulation is the relatively soft design. It is impossible to fix heavy shelves with objects on metal walls and ceilings. Therefore, this approach is relevant for a horizontal base.

The effectiveness of thermal insulation from foam boards can be increased in two ways. Staggered thin sheets with foaming joints. The second option is not limited to isolon. You can also carry out a combination with mineral wool. Polyfoam in this case acts as a hydrobarrier.

If the building is autonomous, then it is better to insulate the facade. This produces less condensation. In addition, the ventilation gap device contributes to the natural weathering of moisture. Inside a metal garage, the organization of forced ventilation will be required and the working area is reduced, everything happens naturally outside.

Conclusion

To insulate the metal garage from the inside, you need to prepare the base. The choice of material should be based on operating conditions. The best options are polystyrene foam, mineral wool (stone) and polyurethane foam. For subsequent decorative finishes, the lining is the best option, so the installation of thermal insulation should be done through the crate.

External or internal insulation

The best option is external insulation. Thus, a dew point shift (condensation formation at the interface between the cold and warm air) is achieved closer to the outer surfaces of the insulation layer. And if you choose the right thermal insulation material with the lowest possible thermal conductivity, then you can achieve a dew point shift to the finish surface. The second positive factor is the lowland interior space of the garage in terms of overall dimensions.

As practice shows, this method is applicable if the garage is a separate building. If the task is to conduct insulation of a structure located in a row of several garages, then heat-insulating processes will have to be carried out from within the building.

Polyurethane foam insulation

Polyurethane foam insulation

Materials for external insulation

It must be noted that the walls and roof of the garage are insulated differently using different materials. And most of all, the roof is thermally insulated from the inside, because the steel sheet that forms it, in this case, will perform the functions of a roofing.

As for the walls, there are several options. Bricking is considered traditional (half or whole). In this case, the brickwork is made for jointing, that is, with the exact installation of each stone horizontally and vertically, with a joint thickness of not more than 8 mm. The seams at the end of the work are leveled with a special tool - a scraper made by oneself or purchased in a store.

There are several positions that must be considered when warming with brick:

- a small foundation is poured under the lining: pouring depth up to 15 cm, width within 12-15 cm,

- the steel sheets forming the roof should create a cornice with a length of at least 15 cm to close the lining from rain and water from melting snow.

Brick exterior metal garage

Brick exterior metal garageToday, manufacturers produce special paints that increase the thermal insulation qualities of metal structures. They include heat-insulating fillers in the form of granules of foam glass, ceramics, perlite or fiberglass fibers. In appearance, they resemble a thick paste, and are applied to metal surfaces with a thickness of 2-4 mm.

This is the best innovative option for insulation of garages, easy to use, but expensive in terms of the cost of the material itself. Therefore, in everyday life, he never received his widespread use.

Materials for internal insulation

We turn to the internal insulation of iron garages, as the most frequently used. All heat-insulating materials that are used for insulation of buildings and structures can be used when conducting thermal insulation of the garage from the inside. So, here is a fairly large list of materials offered.

But for many owners of garages, the question is posed with one addition, how to insulate the iron garage from the inside on their own and inexpensively. That is, two positions are in priority: do it yourself for little money (cheap).

As for inexpensive materials, everything will depend on which building element needs to be insulated. If it is walls and a roof, then it is optimal either mineral wool in mats with a thickness of 100 mm, or polystyrene (household name), it is also polystyrene boards with a thickness of 30-50 mm. But if you make a choice of mineral wool and polystyrene boards, it is better to give preference to the second. There is one reason - low hygroscopicity. That is, the material does not absorb moisture, so after its installation there is no need to cover the warm layer from the inside with a waterproofing membrane. In the case of mineral wool, this will have to be done.

Polystyrene foam boards

Polystyrene foam boards

And one more reason. The installation of foam boards can be carried out on a special adhesive composition. Mineral wool is laid according to the frame technology, which increases the cost and complexity of the work due to the elements of the frame structure.

As for floor insulation, it is best to use expanded clay. It is added instead of crushed stone to the concrete mortar used to fill the screed. And this closes the problem of thermal insulation of the floor base of the garage.

Expanded clay for floor in the garage

Expanded clay for floor in the garage

How to conduct foam insulation

The process of foam insulation of a metal garage is two stages: preparation and installation of insulation. The preparatory process includes cleaning the surfaces of the metal sheets forming the roof and walls from dirt, rust and peeling paint. Any method that guarantees the quality of the final result will do. Most often, ordinary sandpaper is used for this. To increase the speed of the procedure, a grinder with a nozzle in the form of a metal brush is used.

Now about the glue composition. Since the metal structure is exposed to insulation, it is better to use special glue in the can for polystyrene foam boards. This is a universal adhesive material in the form of foam, which guarantees the strength of the insulation to the metal. It is resistant to moisture and temperature extremes. One spray can hold 10 m² of plates, it takes 30 minutes to freeze.

Attention! Polystyrene foam in the volume after its application does not expand, like mounting.

Please note that the walls and roof of the garage are steel sheets welded to the frame of the building. The latter is made of a metal profile, most often from a corner of 50x50 mm. The frame is closed with sheets of iron from the outside, that is, it remains inside. Therefore, it is important to precisely cut the polystyrene sheets to the dimensions of the frame structure so that the insulation lies between the frame elements, snuggling tightly against them. Trimming is done with a sharp knife.

Now glue should be applied to the plates: along the perimeter and along the diagonals. Expanded polystyrene sheets are applied at the installation site and pressed by hand, but not much. Installation is best done from the bottom up. There are several points to pay attention to:

- Insulation plates have a small specific gravity, which makes it possible not to install supporting elements on the vertical planes of the walls. The foam itself is enough. But on the slopes of the roof you will have to think over the supports. One of the options is ordinary tape, one end of which is glued to the insulation, the other to the steel element of the frame.

- If there is a small gap between the plates of the insulating material and the carcass of the garage, you just need to foam it with glue.

Gates and doors are insulated in the same way as the walls of the garage.

Installation of polystyrene foam boards on glue

Installation of polystyrene foam boards on glue

Roof insulation of a steel garage

The option using foam, which is laid on the inner planes of the roof slopes, is the easiest. The structure of the garage structure includes jumpers that hold the longitudinal walls of the structure between them. Sometimes these jumpers are used to form the ceiling. They are hemmed with sheet materials: plywood, chipboard, OSB or iron sheets that are stacked on wooden battens. The latter are attached to jumpers or self-tapping screws, or bolts, or knitting wire.

It is the insulation of the ceiling that will solve the task with the roof. To do this, you will have to lay on top of the jumpers, and these are all the same steel corners 50x50 mm, from the abovementioned sheet material. The sheets are fastened to the jumpers with an ordinary knitting wire in increments of 50 cm. That is, you need:

- drill holes in the flooring on each side of the jumpers,

- insert a wire into them so that the ends hang down from different sides of the frame element,

- to twist the wire along the lower edge, drawing the sheets to the jumpers.

Now foam is glued to the stacked sheets, and then the entire ceiling structure is hemmed with sheets of plywood, OSB, fiberboard or particleboard. Although there are a lot of finishing options.

Ceiling insulation foam

Ceiling insulation foam

Garage Interior

The complexity of the interior decoration of a metal garage after thermal insulation works lies in the fact that there is nothing to fix the finishing material to. If a frame method of warming were used, that is, with the installation of a frame of wooden battens, then the finish would be attached to it. But since the simplest option was considered - frameless, it is necessary to tell how to attach, for example, a plywood sheet to the garage wall.

To do this, you will have to carry out additional preparation, which consists in the fact that a certain number of M6 or M8 bolts must be welded from the inside to the steel sheets forming the surfaces of the garage structure. It is necessary to weld hats to sheets of iron.

The length of the fastener is selected based on the thickness of the insulation and the thickness of the finish. For example, the thickness of the foam is 50 mm, the thickness of plywood is 8 mm, which means that bolts 70 mm long will be required, where 12 mm will be used for fastening with a nut and washer. The number of fasteners is determined by the distance between them. There is no exact data, therefore approximately 40-50 cm.

The process of insulation on the fasteners is carried out in the following sequence:

- the adhesive is applied to the foam sheet,

- it is installed in the required place and pressed tightly with your hands,

- insulation - the material is loose, so that the bolts through it pass easily,

- finishing material is cut to the required size,

- the ends of the bolts are treated with chalk or paint,

- apply the finishing panel to the desired place, traces of chalk or paint will remain on its surface,

- holes are marked on the marks with a drill and drill, the diameter of which should be slightly larger than the diameter of the bolts,

- the finishing panel is put on fasteners and clamped with nuts, under which wide washers must be placed.

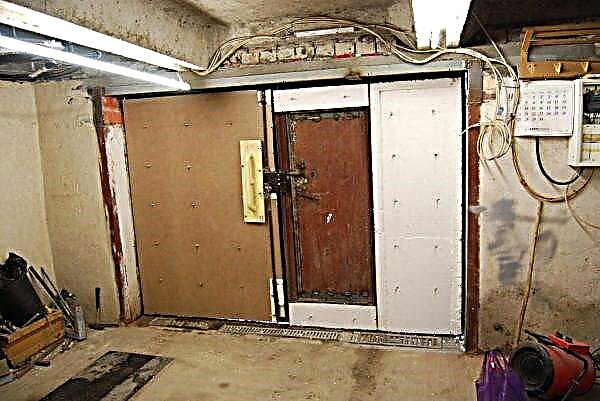

Fastening foam and fiberboard to garage doors

Fastening foam and fiberboard to garage doorsInsulation of the garage from the inside with a brick

There are no contraindications to use a brick to insulate the garage from the inside. Just brick lining will reduce the volume of the structure. This is a more complex process in terms of work, it is more expensive than the use of foam. In addition, the brick in terms of thermal conductivity is much inferior to polystyrene plates:

- 0.81 W / m K - thermal conductivity of solid brick,

- 0,032 - 0,044 W / m K - the range of thermal conductivity of the foam, depending on its density.

It turns out that the foam laid in a thickness of 30 mm replaces the masonry of three bricks laid along.

Polyurethane foam for garage insulation

And a few words about polyurethane foam, whose thermal conductivity is 0.019 W / m K. That is, it is better than polystyrene. But it is more expensive, and special equipment is required to apply it. More recently, such equipment was a huge tank and compressor. Today, manufacturers offer compact devices whose weight does not exceed 30 kg.

These are two cylinders and a mini-compressor with hoses and nozzles. There are two components in cylinders that are connected and fed through hoses under pressure. A small thickness of the applied layer (15-20 mm), pay attention - continuous, without seams and joints, more effective than many modern thermal insulation materials used for insulation of garages. But if you compare at cost, then he loses all the same foam. Although good insulation cannot be cheap.

Insulation of a metal garage with polyurethane foam

Insulation of a metal garage with polyurethane foam

There are several effective and inexpensive technologies for warming iron garages. But, as practice shows, most often use polystyrene if the conversation is about the processes carried out by oneself. There are no restrictions or contraindications to the use of this material. At the same time, the insulation has a number of good technical characteristics, plus the low price of the product itself.

Tools required in the process of warming a metal garage with your own hands

- Thermal insulation.

- Wooden bars for the device of the lathing.

- Fasteners.

- Foam for sheltering cracks, joints.

- Construction tape.

- Waterproofing material.

- Screwdrivers, screwdriver.

- Vapor barrier material.

- Hammer.

- Corners made of metal.

You will need material for finishing, fasteners, for a specific material.

Insulation for metal garages

Warming of a metal garage occurs, after selecting the material. How to insulate an iron garage from the inside? This is a responsible process. How to insulate? What material to choose to serve most efficiently and optimally suited for insulating the garage from the inside with your own hands? Additionally, you need material for finishing, as well as fasteners, for a particular material.

The most popular thermal insulation is polystyrene, but there are a lot of various options:

- liquid insulation

- foamy insulation

- plates for insulation of different strengths (polystyrene foam, polystyrene foam),

- fibrous soft plates.

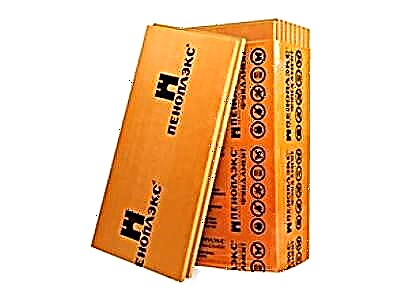

Extruded polystyrene foam (penoplex)

This material is a type of foam. The option is superior to conventional polystyrene in all respects:

- in terms of strength, foam can be used to warm the garage floor and mount the screed directly on the insulation,

- thermal insulation properties are 3 times higher

- a three-millimeter sheet of foam (polystyrene foam) replaces a 5-centimeter layer of foam,

- Penoplex is an ideal waterproofing agent, its use is possible even in water,

- the only negative is the cost, it is almost 2 times higher than the cost of polystyrene. For many, the price of warming an iron garage is an essential point.

Thick fiber insulation

Plate - fibrous material is not the best for warming a metal garage, no matter how dense a slab or mat made from minvolokn, it is susceptible to the harmful effects of moisture. At the slightest moistening of the insulation, its properties drop significantly and it does not perform its function properly.

Insulating min with a cotton wool metal garage is not recommended, it is important to know. Condensation will form on the insulation even with waterproofing.

Liquid insulation

A common liquid insulation is heat-insulating paints Astratek, Corund. This is an expensive but quick way to insulate a metal garage from the inside.

A 1mm layer replaces a 50mm mineral wool slab. Apply paint with a brush or roller. The coating is moisture resistant and durable. Service life is up to 15 years. To provide a coating of 1 mm thickness, 1 liter of paint per 1 m2 is required. Specialists recommend applying in two layers.

Design insulation options (garages, shells)

How to insulate a metal garage with your own hands? With liquid heaters, everything is very simple, a brush is taken, a roller is coated on the surface.

Do-it-yourself insulation of a metal garage has several options, inside or outside the structure. Insulation from the outside in this case is not the right way. Consider the methods of internal thermal insulation:

- Before carrying out work, a foundation should be prepared. This stage is important, and it cannot be ignored, in order to avoid rust and detachment of the insulation. Corrosion is the main enemy of metal products. First of all, the metal is protected from rust,

- An unpainted base is treated with a metal cord brush. Or on a grinder (drill) put a special nozzle. Thus, the work process will accelerate. The sheet with the old exfoliated paint is also processed

- If the surface has a high-quality coating, it should not be removed. Under the insulation, the paint will remain unharmed for many, many years,

- If the garage is made of galvanized profiled sheet, with a frame made of profiled pipes and a corner, then this material already has reliable protection that cannot be violated,

- After cleaning the base, the surface is degreased (acetone, etc.),

- If you cover the metal, wake up with foam (penoizol), then the preparatory measures taken are enough. If the foam will serve as a heater, it is necessary to paint the iron. It is possible to cover with Kuzbasslak, it is economical and reliable.

Arrangement of the battening of the gate

- After fixing the crates, the slab material is cut to the desired size (as accurately as possible to avoid large gaps).

- It is glued to the base, seams are closed with foam.

- Next, finishing is done by distillation or other material. Also used for sheathing OSB panels, plywood.

Isolon or an ordinary layer of foil glued on top of a foam sheet multiplies the heat-reflecting effect several times. Many heat the premises of the garage "UFO" emitter. Rays from the foil base are well reflected, even under the casing.

Do-it-yourself insulation of the garage floor from the inside

According to SNiP, if the foundation of the room is not insulated, then the loss of thermal energy is 20 percent. Also in the garage, the floor plays a crucial role in the microclimate of the room. The insulation blocks moisture coming from the concrete base.

Floor insulation foam:

- the soil is removed, about 15 centimeters,

- then the surface of the base is leveled and compacted,

- first a sandy layer is poured, which should be tamped,

- then stacked foam plates, 5 cm thick. With a flat surface, the joints will be even and dense. Moreover, there are grooves in the plates.

- the material does not need waterproofing, since it is an excellent waterproofing material,

- 3-4 cm of sand is poured on the Penoplex,

- then the frame is connected in two layers of 10 mm reinforcement,

- poured with a screed of 5-8 cm.

For complete insulation of the floor, a blind area device is necessary, many skip this stage. If the area around the structure allows, it is recommended to carry out these works in order to avoid freezing of the soil under the metal garage.

The width of the device corresponds to the level of soil freezing in the area. As a rule, a blind area is made from 50 cm to 1 meter.

If there is no possibility of carrying out floor insulation as described above, then it is possible to apply the method of false floor. Mounted from wooden logs, insulation and screed. In this process, it is important to treat the wooden logs with a moisture insulating compound so that the tree does not absorb moisture from concrete. It is possible to use roll waterproofing (tech. Polyethylene, roofing material).

Instead of screed, you can lay the flooring (grooved board, 1.6 cm plywood in two layers):

- a high-density foam or polystyrene foam 50 mm thick is laid between the lags

- the gaps are foaming

- flooring is attached to the lags from above,

- logs from each other should be located at a distance of 30-40 cm. For the smallest attrition of the floor, linoleum can be placed on top.

Warming a metal garage from the inside with your own hands is a simple process. You should carry out simple activities in stages and the result will please you. High-quality work - a guarantee of a well-insulatedabout premises for a car. A warm garage is very necessary, especially in the autumn-winter period.

Plate insulation

- As in the past, and to this day, when warming metal structures, one of the most popular materials are foam boards. Such a popular love is associated primarily with affordable value. But this is not the only merit of the old polystyrene foam. These plates are not afraid of moisture and in normal conditions of a closed garage can serve at least 25 - 30 years. Of the negative qualities in our case, only combustibility can be called, although here the market offers PSB-S self-extinguishing plates,

- The closest relative and competitor of polystyrene is extruded polystyrene foam, in our country better known as Penoplex (by the name of the manufacturer). This material by almost all characteristics bypasses its predecessor.

The strength of Penoplex is enough to fill the screed on it and put the car on this screed. In terms of thermal insulation, it is better by about a third, polystyrene foam 30 mm thick, easily replaces a foam sheet of 50 mm.

If the foam partially passes air, then Penoplex is considered a reliable waterproofing and can be mounted even under water. Everything is good in it, but that's just the price, almost 2 times higher than that of polystyrene, and for most owners of metal garages this is important.

Penoplex with connecting grooves.

Cotton insulation

Here I will immediately disappoint you. Whatever the density of the fibrous plates or mats, they are all subject to the same adversity. These materials do not tolerate moisture even in small doses. When wet by 1%, the insulating properties of any of these heaters fall by 7 - 9%.

Hello, but I don’t know how to insulate the garage, i.e. what will be better and its sequence ..

Edward, the type of insulation depends on the material of the garage. A metal garage can be insulated with ultra-thin thermal insulation (special paint). Brick, concrete - polystyrene, extruded polystyrene foam. Wooden - mineral wool.

Tell me how you can insulate a metal garage simply and quickly

Sergey, it is easiest to insulate a metal garage with ultra-thin thermal insulation or, as it is also called, liquid ceramic thermal insulation. In essence, it is a liquid painting ceramic multicomponent composition based on a polyacrylic system in which closed-porous fillers of different bulk density are weighed to create a syntactic foam. Thermal insulation KORUND Classic and Armor are highly effective in thermal insulation of roofs, building facades, internal walls, window slopes, concrete floors, hot and cold water supply pipelines, steam pipelines, air ducts for air conditioning systems, cooling systems, various containers, tanks, trailers, refrigerators, etc. It is used to eliminate condensation on cold water pipes and reduce heat losses according to SNiP in heating systems. The material is operated at temperatures from –60 ° С to + 200 ° С (up to + 260 ° С in the peak short-term mode). The service life of the material subject to the rules of the application technology is at least 15 years. Today, our material is used at facilities and enterprises in various fields of activity.

Hello, I have a panel-mounted prefabricated garage, please tell me the better it is to insulate.

George, to insulate the shield garage from the outside, it is necessary to install profiles under the external finish and fix the insulation layer on them.

Insulation can serve as bulk and sheet materials: