Fencing, fully welded from a profile pipe

In our small village, about a fifth of all new fences, gates and gates from profiled sheets are welded by the hands of my husband. This material is now very popular, since it does not cost much more than a wooden fence, but serves, without losing sight and without requiring repair, much longer.

But the frame for it must be strong, reliable and durable, and the wooden supporting posts and logs can not be called such. The husband works exclusively with a profile pipe, from which other designs have also been made.

But the Chukchi is not a writer, the Chukchi is a reader, so I sing the praises of this material from his words. Moreover, I am familiar with the topic firsthand - often I have to act as a helper.

Profile pipes are preferable to round: 1 why

From the point of view of the master, everything is clear:

- Square or rectangular pipes are easier to work with..

- They are easier to transport - do not roll out, fit tightly, take up less space.

- Another plus is the rich selection of sizes, but more on that later.

Pipes differ not only in section size, but also in wall thickness

But customers also believe that a profile pipe for a fence is preferable to a round one, since it looks more attractive, especially against the background of clear rectangular fence lines made of a metal fence or a profiled sheet. In addition, it often costs less or as much as the round timber.

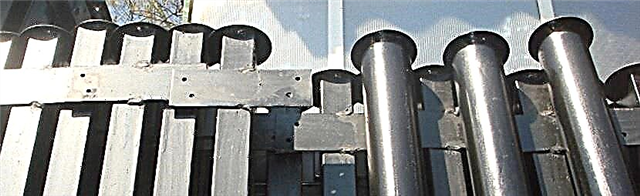

But if the fence is made of welded wire mesh or netting, pipes of circular cross section with hooks welded to them are used for supporting posts.

The advantages of metal supports

We list only the main advantages of metal columns:

- The strength of the metal.

- Metal pipes on the fence have a high bearing capacity. Such supports can safely be attached to heavy materials such as asbestos cement slate and metal sheets.

- The lifetime of iron supports is several decades.

- The pipe on the fence can be used repeatedly. For example, when moving the fence to another place.

- Installation of metal posts for the fence is quick and with minimal effort.

- Supports, especially galvanized, exhibit increased resistance to weathering.

- Metal supports are easily processed and coated with any liquid composition.

- Fence sections can be mounted in various ways: bolted, clamps, welding.

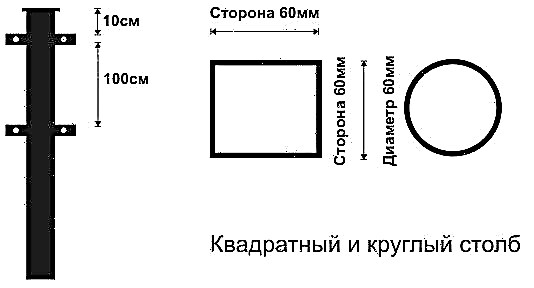

What to choose the cross section of iron supports

Pipes for the fence can have a round, rectangular or square section:

- Round iron supports are preferred if they can be driven into the ground or screwed in using a special tool. They are used mainly for fences made of mesh-netting, picket fence, slate.

- Rectangular and round products are good if the fence is installed from a profiled sheet. Pits are dug for them, which, after installing the racks, are covered with rubble, broken bricks, construction waste, and then concreted.

To find out which ones are better, you need to determine in advance the type of material from which the posts will be installed for the fence. It is believed that it is more convenient to work with profiled products than with round ones, and the installation turns out to be better. It is easier to fasten any material to profile products, while round pipes on the fence require welding of additional fasteners.

Overall dimensions of pipes

We list the main dimensions of the metal pipes used for the manufacture of fences:

- The thickness of the pipe walls. It can be in the range of 1-12 mm. In our case, it is necessary to ensure that the walls have a thickness of at least 2 mm. It is better to choose a thickness of 4-5 mm.

- Section Diameter This parameter directly affects the stability of the supports. The larger the cross-sectional diameter, the more reliable the stand will be in the ground. However, pillars that are too thick should also not be used. Firstly, their installation will be fraught with significant difficulties, and secondly, under their own weight, such supports can be skewed. Diameter 100x100 mm is the maximum allowable for the manufacture of fencing. The optimal diameter for the main supports is considered to be 57 mm for a circular section, 60x60 mm for a square, and 40x60 mm for rectangular supports.

As intermediate supports can be used pipes, both having a diameter of 60x60 mm, and thinner. For example, 50x50, 50x40, 40x40 mm.

- Length. The standard lengths of iron pieces are 1.5, 3 and 6 m. Of course, they can be cut into pieces of the length you need. If you purchased pipes, say, 1.5 m, and such a length is too small, the products can easily be increased by welding. The final length of the pipe on the fence is selected more by 50-70 cm than the planned height of its installation. This is based on the fact that at such a depth the iron support will go into the ground. On sandy and loose soils, installing a pipe may require a more solid deepening, up to 1 m or even more.

Pipe coating

In most cases, iron pipes are installed in the ground exactly in the form in which they were purchased. After installation, they are sanded, primed, and then painted. Re-staining is done as the paint ages. If the supports are not painted in a timely manner, the metal will begin to become corroded. Galvanized pipes with additional protection in the form of a layer of zinc successfully resist corrosion.

Galvanized steel profile pipe

Galvanized steel profile pipe

Why is it better to buy galvanized supports? For such reasons:

- They will serve much longer than unprocessed columns, even if they are not painted on top.

- Galvanized pipes have a cost slightly higher than the price of conventional metal products.

In addition to galvanizing, the pipe on the fence can be coated with a polymer layer. This type of coating is relatively new, but has already proven itself in practice. Polymer-coated pipes do not require any additional processing at all. Immediately after the purchase, you can carry out their installation on the site.

How to install metal pipes for the fence

For the installation of pipes for the fence to be of high quality, it is necessary to comply with certain requirements for the installation of the fence. The following conditions must be taken into account:

- The distance between adjacent posts. The average distance is assumed to be 3 m. This section length will allow the fence to maintain its rigidity and the necessary compliance with wind loads. If the fence is made of heavy material such as slate or sheet metal, then the distance can be reduced up to 2 m. As an option - the installation of intermediate poles, partially taking on the weight of each section of the fence.

- The required number of posts. Knowing the distance between the columns, the required number of pipes is easily calculated. To this amount is added 2-3 columns necessary for the installation of the gate and gate.

We have analyzed the main varieties and parameters of pipes used for the construction of fences. Which pipes are best installed is decided on the spot. Much depends on the range of products in your warehouse, the cost of products, your individual preferences and financial capabilities. Sometimes it’s better to overpay a little, but to purchase high-quality and coated products. In this case, you are unlikely to have to doubt their durability and bearing capabilities.

Design features

Metal pipes for a fence installed on a private housing plot or cottage are divided into two key groups:

- with a circular cross section

- profile products.

In turn, the second option is more common in two versions: square, rectangular metal pipes on the fence. Round poles are more suitable for structures such as mesh fencing (made of netting and welded material). In this case, the fastening is carried out using metal hooks installed by welding on the fence pipes. This solution allows you to increase the tension of the mesh material.

Profile analogues are usually used when installing a profiled sheet and metal fence. This option can be equipped with embedded parts, which greatly simplify the task of installing the fence, in particular, fixing the lag. Intake pipes are sometimes offered with protective elements at the end sections. This reduces the chance of moisture entering the product.

Pipe length: how to make a choice?

Metal pipes are led into the fence quite deep under the ground: from half a meter to 1.5 m. Different requirements are imposed on the ground and buried parts.

During the installation of fencing from corrugated board with a height of 2 meters, it is necessary to choose a length of at least 3 meters.

The protruding section of the support can be lower than the upper edge of the fence only when it is used as reinforcement of a stone or brick pillar.

When constructing a fence around a private house or in a country house made of corrugated board, mesh, forged sections, the metal fence pipe should be flush with the top edge of the construction filling. Accordingly, in this case, the support posts will rise above the lags, if provided.

For convenience, it is recommended that during installation, preference is given to a profile pipe, it has an excellent appearance, easier during installation work.

The metal pipe for the fence can be installed in the soil to a depth slightly greater than the boundary of the watery layer. In this case, the location of the support stand should be deep (1.5 m), it all depends on the characteristics of the soil in a particular area. If the watery layers are laid low, it is advisable to install poles under the fence in the country house no deeper than 1 m.

For the lightest structures, it is enough to prepare holes up to 0.5 m deep. Accordingly, the metal pipe for the fence in total may have a length of 4 to 2 m, it all depends on the soil structure, as well as on the height of the fence.

Section selection

The degree of strength of the material under the support poles is determined by the level of exerted loads: the higher they are, the greater the cross-section of the column should be. The preferred value of the thickness of the product depends on this factor.

The metal pipe on the fence can be round, square or rectangular, respectively, the level of reliability directly depends on the shape. For example, profile products have stiffeners that make them more resistant to stress. This means that for heavy structures this type of support is chosen.

The metal pipe on the fence can be round, square or rectangular, respectively, the level of reliability directly depends on the shape. For example, profile products have stiffeners that make them more resistant to stress. This means that for heavy structures this type of support is chosen.

The metal pipe on the fence may have a wall length of 40 to 100 mm. The diameters of round products are in the same range. For structures with increased sailing, it is recommended to choose materials for fence posts with a minimum cross section of 60x60 mm. It is preferable to build the heaviest fences in the country using racks 80x80 mm and 100x100 mm.

As regards the wall thickness of the posts, 2.5 mm and 3 mm are preferred for medium and heavy structures. Light hedges are mounted using pipes with a wall thickness of 2 mm.

Cost determination

On average, a metal pipe on a fence is offered at a price of 130 rubles. up to 700 rub. for pog. m. The most affordable products are characterized by a small wall thickness (2 mm) and a cross-section (60x30 mm).

The main characteristic that affects the life time of a metal column is the wall thickness. This indicator is also associated with the cost, because the weight of the metal and its price indicators are directly proportional.

Accordingly, the most expensive pipes (3 mm, 100x100 mm) can be bought for 450 rubles / line. m. If we consider even more reliable products (4 mm, 120x120 mm), its cost reaches 700 rubles / pog. m

How to protect the product from corrosion?

To solve this problem, different methods are used, which together allow to extend the service life of the finished structure:

- Anticorrosive compounds and paints and varnishes. If you plan to build a fence at the cottage on your own, you need to carefully approach the choice of metal materials. It is recommended to purchase products under the pillars without finishing, that is, without coating with paint. It is enough to buy primed pipes. This need is explained by the fact that during transportation and during operation, the paint is scratched.

- The top is mounted on the pole. This is a decorative element that additionally performs another function - it protects the support column from the penetration of moisture into the internal cavity.

Also, metal pipes are often used, in which the lower end installed in the soil is welded. All these measures contribute to increasing the resistance of the material to rust when in contact with water. If you purchased an unprotected metal pole, you need to take care of its coating with a primer and paint, and it is advisable to apply 2 layers of material.

For heavy fences, a more durable material is suitable - pipes with a section of 80x80 mm and higher with a wall thickness of 3 mm. The average version of the fence implies the need to use racks with a cross section of 60x60 mm or more, the thickness of the material is 2.5 mm. Lightweight hedges are constructed using pipes of minimal cross section (from 40x40 mm and above, wall thickness 2 mm).

Calculation of the number of pipes

In order to start the construction of the fence, you must first calculate the number of pipes

The amount needed for installation can be calculated as follows: divide the total border length by the distance between the supports. It is recommended that the distance separating the pillars is:

- 2-2.5 meters - for round pipes

- 2-3 meters - for profile ones.

It is important to remember that if the weight of the structures increases, the distance between the supports should decrease. The distance also varies from the quality of the soil: the frequency of the posts increases with its softness.

Types and materials

Due to certain safety factors, the pipe for the fence posts is selected from metal. Such designs can be figuratively divided into the following types:

- Sectional fencing - consist of several sections manufactured in factories. The construction of such a design involves hanging the partition to the profile pipe.

- Welded fences. To obtain them, the frame is welded from the profile with the fastening of decorative elements.

When constructing fences from pipes, they also resort to additional materials:

- Profiled sheet. A popular combination, it is easy and quick to install, because sheets are ideally combined with profile designs.

- Tree. Typically, wood is used to decorate frames.

- Metal grid. It is used for the construction of simple and practical fences. Most often, such constructions are prefabricated, because manufactured in factories.

- Forged Products. Forging is often resorted to decorating metal intake pipes.

How to choose

As mentioned earlier, a fence is an integral part of most buildings, for example, for a summer residence. The use of metal pipes for the fence is an ideal solution: they combine lightness and ease of installation, have a fairly small weight and tough resistance to weather conditions.

Equipping the fences, you need to responsibly and conscientiously treat the selection of pipes. Thanks to this, both time and money are saved, and the need for frequent repairs of the fence is avoided.

For orientation when choosing a very important parameter is the size of the profile pipes.In addition, there are other equally important properties:

- Cross-sectional area. With increasing area, the pipe resistance in the foundation increases. Conversely, with a lack of value for this indicator, there is a high probability that the fence will fall in whole or in part.

- Steel grade. The choice of steel depends on the desires and financial capabilities of the buyer. You can opt for galvanized pipes that are resistant to corrosion and have a long service life, or you can limit it to black steel products that require more careful maintenance.

- Pipe length. At the stage of calculations, in addition to the external height, it is also necessary to take into account the depth of digging into the soil, and they are brought rather deeply, by 0.5-1.5 m. The sailing is a very important point here, the stability of supports with lining should withstand wind gusts.

Estimated prices for pipes of different sizes

The assortment of pipes is quite large, and it is advisable to study market prices before building the fence. Thanks to this, you can pre-calculate the cost and plan your budget in advance. First of all, you need to decide which pipes will be used and how much will be needed. It is more convenient to calculate the price for one running meter of the product. It is easy to calculate the cost of professional pipes by determining their total footage.

Rectangular pipes with a section of 40x60 mm and a thickness of 2 mm are sold at 110-120 rubles / pm. For more durable fences, poles with a section of 80x80 millimeters, where the walls are 3 mm, are useful. Their price ranges from 260 to 290 rubles per linear meter.

The price of a square shaped pipe with sides 100x100 mm and walls of 3 mm is calculated from 360 rubles / pm.

Pipes of a small section, 40x40x2 mm in size, cost approximately 66-74 rubles, and columns with a profile of 60x30x2.5 mm - approximately 95 rubles.

How to install the pipes for the fence

There are 4 options for installing pipes, you can choose any

Having decided on the pipes for the fence, you need to make a sketch of the docking nodes and only then proceed with installation. Installation of a metal fence is a fairly simple task, which requires, mainly, the skill of welding and the ability to handle metalwork tools.

Installation begins with the installation of racks, but before that they clean and level the terrain under the fence, make markings.

Pillars are assembled using the following methods:

- Driving into the ground. Support blows with a sledge hammer are buried in the ground at 1/3 of its length. This method is applicable for low-stony soils.

- Backfill and ramming. The column is laid in the excavated cavity and is fixed by filling with gravel and sand.

- Partial concreting. The lower part of the base is poured with concrete, and the rest is covered with earth and then rammed.

- Full concrete pouring. For supports, mines of the required depth are excavated, the bottom of which is covered with a mixture of sand and gravel for drainage. Then they are installed poles and poured concrete.

Important note: the last method is considered the most reliable, because it is he who guarantees the best fixation. The rest, due to the instability of soils, can be ineffective and lead to deformation of the entire structure.

Logs and their installation

The logs with which the corrugated sheets are fixed are installed using the following techniques:

- Overlap. Logs are laid on poles and fixed by welding or self-tapping screws.

- Butt The guides are attached to the posts by T-shaped welding.

- In the slot. In the vertical base, holes are made above and below through which the guides will pass. They are also fastened by welding.

After installing the frame, proceed to the decorative coating. The methods for attaching it depend on the cladding material used. So, the professional sheet is attached simply by screwing on special screws with sealing rubber bands on the heads.

Installation Standards

A very important fact in the construction of the fence is the calculation of the location, because There are certain rules that are required to comply. This is a SniP - a document in which all the norms and distances from buildings are fixed.

The fence should be from the land of neighbors at a distance:

- Three meters from the apartment building,

- Four meters from the buildings with pets,

- One meter from any other kind of buildings,

- Two meters from low trees, four from tall and from bushes - 1m.

In addition, the height of the fence should be no more than 1.8 meters and the distance from the underground gas pipe should be at least 1 m. You can get documents that specify the standards from representatives of local authorities. So that in the future there is no need to resort to demolition of the fence, it is only possible to proceed with its construction after agreeing on all installation issues.

The advantages of a metal profile pipe in the construction of the fence

Profile metal pipes will last for decades, unlike wooden ones.

The long service life of the fence structure depends directly on the material of which the supporting frame is made. It is unlikely that a fence with a wood frame will last longer than 10 years. There is a more reliable option - concrete, but when installing such structures there are difficulties in fixing the girders.

Based on this, we can conclude that metal profile pipes are the best basis for the fence. They are distinguished by their durability, strength and adaptability during installation. On this frame, any material for the fence is easily fixed. Developers chasing budget options are scared by the high price. But, if you compare the life of the fence made of wood and metal, you can easily convince anyone of the opposite.

A metal frame will last at least 50 years, when a wooden analogue requires replacement 3-4 times. This is a strong argument in favor of a metal pipe.

Profile pipe - a material having only one minus - it must be protected from corrosion. But it is easy to deal with it, for this, before facing the pipe, it must be primed and painted with compounds protecting it from aggressive climatic influences.