The primer for wallpaper is one of the most important elements of repair. Many masters ignore the need for priming walls, going directly to the finish. However, in practice, neglect of this stage negatively affects the result and the life of the wallpaper.

The priming of the walls for wallpaper should be done for several important reasons. Firstly, using this composition it will be much easier for you to make the surface of the walls monophonic. Moreover, the material will hide any defects in coatings. This is especially important for pasting light and transparent wallpaper.

Primer conceals coating defects

Secondly, the primer will make it possible to completely hide before finishing the place where dirt and dust can accumulate. Thirdly, the mixture can fill the pores formed in the starting material. After that, wallpaper glue will not leak through the cracks, which will guarantee a more reliable fixation of the film on the walls. The primer improves the reliability of the setting of various materials among themselves. That is why the mixture is often used not only before wallpapering, but also during other repairs.

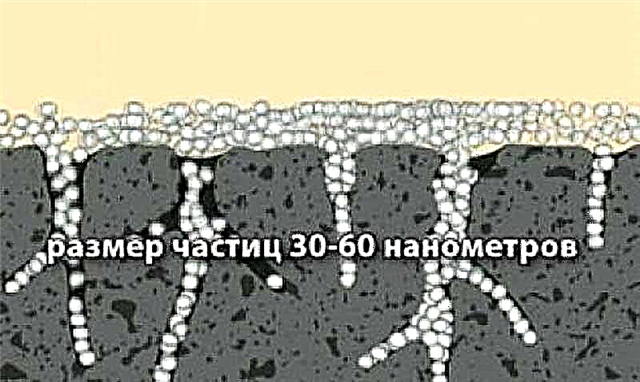

The primer is a liquid suspension, which during application is able to penetrate 2-3 cm deep into the septum. The stronger the wall surface, the more concentrated the deep penetration mixture should be. If you need to get a smooth and durable wall surface, then for this you should choose a rich, thick primer. To answer the question: “Which mixture is best to choose?”, You should find out what material the walls of the house are made of.

The simplest primer can be even ordinary glue for wallpaper. It also to some extent reduces the ability of the coating to absorb moisture. However, glue will not protect the walls from dirt and stains. Therefore, it can only be used if you already have a perfectly flat working surface at your disposal. For other coatings, it is worth choosing one of several types of primers. In addition to the wall material, the buyer must also take into account the drying time and other important properties of the mixture.

Depending on the main active components, the following primers can be found on the market:

- perchlorovinyl

- glyptal,

- acrylic

- mineral

- alkyd.

Each of the presented types of material has certain properties, advantages and disadvantages. Only by studying them, you can choose the soil suitable for a particular surface.

The most versatile and often used is considered an acrylic primer. It is worth choosing for the preparation of brick¸ plywood, wood and concrete walls. However, the use of this composition is strictly prohibited for the treatment of surfaces for the construction of which ferrous metal was used. Among other properties of acrylic soil, its quick drying can be noted. On average, it takes no more than 6 hours. Such material is absolutely odorless and easy to dissolve in water.

When buying, you should try to choose the highest quality acrylic primer. In practice, it is best to trust the products of well-known companies. Remember that some sellers sell ordinary PVA glue under the “mask” of the primer, in the production of which no acrylic polymers are used at all.

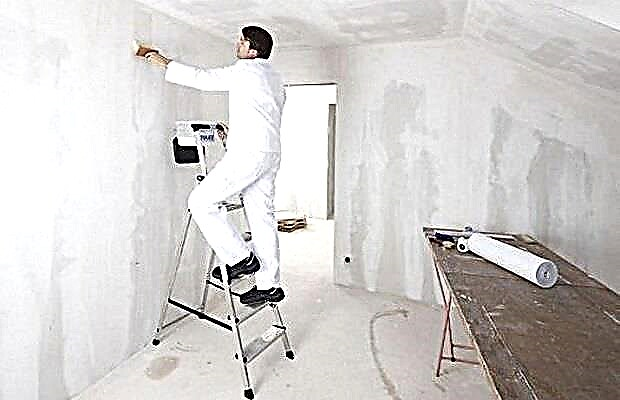

Primer walls before coating

Alkyd-type mixtures are most often used for the treatment of wooden walls. Therefore, they are very popular among owners of cottages. Immediately after the material is applied to the wall, a viscous layer forms on the surface, which can cope not only with wallpaper, but also with heavier materials for decoration. Depending on the composition, alkyd soils are divided into mixtures with zinc chromate and primers with zinc phosphate. Materials of the second type are used to impregnate partitions immediately before the finish painting of the walls. The second type of mixture is useful for wallpapering. Among the main properties of alkyd soil, it is worth highlighting a long drying period - about 14-16 hours.

This material is often used for laying tiles, it has been successfully used both inside and outside the building. And in fact, and in another case, it guarantees perfect adhesion of the finish to the surface.

If you work with metal walls and partitions, glyptal soil will be the best option. In fact, this is the only type of impregnation that allows high-quality processing of surfaces made of metal. Therefore, most often it is used for wallpapering in garages or plastic buildings. Glifthal composition is absolutely harmless, it is often used without special protective masks. This impregnation has a high level of strength, it does not wear after application, which is very similar to enamel. The drying time of the mixture is from 8 to 12 hours.

Concrete Wall Processing

Mineral primers are excellent for working with concrete partitions and walls built of expanded clay concrete and gas silicate blocks. They are also often used for application on brick surfaces. As a basis for a primer gypsum, lime or cement is used. When buying mineral impregnation, note that the selected composition must match the working coating. On the surface, which includes lime, you need to apply lime and gypsum soil. For concrete walls, any other impregnation is suitable. The drying time for mineral primers is from 3 to 24 hours.

Another type of impregnation intended for metal processing is perchlorovinyl primer. Also, this material is often used for application on brick and concrete walls. A great advantage of the primer is the possibility of its use in late autumn and early winter. Among other advantages of the composition can be noted short drying times - in an hour the walls will be ready for wallpapering. It is also worth considering the high degree of adhesion and the antiseptic properties of the impregnation. The disadvantages include the high toxicity of the material, so you can apply such a primer only in a special mask.

When studying the characteristics of each type of primer, you may have a question: "What to do with liquid wallpaper?". In their composition and consistency, they completely repeat decorative plaster. The only difference is that the basis of liquid wallpaper includes silk and cellulose fibers. To prime them, it is worth using a white suspension or a completely transparent emulsion. In the process of leveling the surface requires 3-5 layers. In the future, this will help to avoid stains that appear after applying liquid wallpaper.

Aligning the walls with acrylic

If a primer containing quartz dust is used for liquid wallpaper, then before using it, it is worthwhile to pre-level the walls with an acrylic composition. So you will be insured against roughness and tears, and the material on the prepared surface will lie more evenly. To summarize, it can be noted that liquid wallpaper also needs a primer. Moreover, in order to apply this type of finish, it is worth following the color and texture of the impregnation. Otherwise, you may spoil the appearance of the surface.

Ignoring the need to apply the soil, first of all, is explained by the unwillingness to spend money. Plus, most manufacturers of adhesives guarantee high-quality adhesion of wallpaper to their products. In fact, the use of a primer is not always considered a necessary measure.

Firstly, you can not use impregnation when performing temporary repairs of housing, or when the wallpaper itself was not originally designed for long-term operation. Secondly, the soil can not be used in the case when you want to glue light wallpaper made of paper. At the same time, the primer significantly increases the adhesion of materials. As a result of its use, the finish will be faster and more reliably fixed on the base. Impregnation easily and quickly penetrates even the smallest pores of the wall, thereby preparing a perfectly flat surface for applying glue.

Types of primer for wallpaper

Primer for walls under the wallpaper otherwise called a primer. Being auxiliary, the material determines the success of the finishing work. Here is a paradox. In other words, you can do without soil, but the finish will be short-lived and sloppy.

Preparing for decoration, you need to choose one of 4 compositions:

- Primer for wallpaper. The specialized composition is adapted to cover walls and ceilings with sheets of paper, non-woven fabric, fiberglass. Liquid wallpapers are also on the list. However, behind the alluring phrases of marketers and a solid price tag, soil is hidden on the basis of diluted PVA glue. This can be made independently for a penny.

- Wallpaper glue. Some packages indicate that the contents can be used simultaneously as a bonding agent and primer. Such adhesives are worth the track of others, but are more profitable than a standard primer.

- Acrylic primer. The polymer composition, like the previous ones, dries quickly and does not smell. It is important for indoor decoration. The dried primer, like PVA-based formulations, in solidified form is similar to an elastic film, but insoluble in water. Acrylic primer for wallpaper there is a superficial and deep penetration. The latter goes deeper into the base by 5 or more millimeters, - ideal for strengthening porous, unreliable bases.

- Alkyd Primer Used for wallpapering of wooden surfaces. Porous boards. Alkyd film eliminates the "leakage" of glue and other materials into the base. This reduces trim costs. However, alkyd soil is universal, good not only on wood, but also on metal, concrete. Minus - the toxicity of the primer, which is due to its unpleasant odor. In addition, alkyd soil dries for 15 hours.

Sometimes it is required to prime both the wall and the wallpaper. The latter are for painting. To paint perfectly lay on the canvas, they are also coated. By purpose, primers for wallpaper are only strengthening and leveling, or also antiseptic.

The latter are good for treating bases affected by fungi. Their development is blocked by fungicides added to the soil. They are still used in agriculture for seed treatment in order to free them from fungal spores.

It turns out, in the question, what primer to choose for wallpaper There are several factors to consider. Often, specialist advice is required. By applying the wrong primer, for example, it is possible to corrode metal elements that come to the surface of the wall. Water-dispersed soils will attract moisture in it.

Features primer for wallpaper

Need white primer for wallpaper. This is a basic compositional requirement. Color primers can shine through, affecting the tone of the final paintings, their perception. In addition, white perfectly masks the spots on the wall, its imperfection.

In order for the primer to give a saturated white color, the composition is often pigmented. Light particles are added to both acrylic and alkyd soils. Options based on PVA are already white.

Pigmented primer for wallpaper sold along with whitened primers for other coatings. It happens, for example, acrylic impregnation for decorative plasters. Such a primer, when dried, becomes rough. This enhances the topography of the plaster.

Consumption and application of primer for wallpaper

Primer consumption depends on its type, the nature of the substrate and its porosity. If there are many internal voids, microcracks in the wall or ceiling, an additional primer volume will be required to fill them.

If the base is dense, with a minimum of pores, soil consumption will decrease. When applying the primer in a single layer, the minimum volume of the mixture is spent. The more layers, the higher the soil consumption.

The average figures per 1 square meter are as follows:

- 50-100 milliliters is spent on acrylic soil, but deep-penetration compounds can also be absorbed per kilogram per square

- alkyd primer per square takes 100-150 milliliters

- about 200 milliliters of specialized soil for wallpaper

- 100-150 milliliters spend wallpaper glue as soil

It should be noted that primer for liquid wallpaper, or non-woven, paper, fiberglass is used differently and differently. Flizelin and fiberglass, for example, are heavy.

In order to keep such a mass on the wall, maximum adhesion is needed, that is, the penetration of glue into the base. Accordingly, one has to take primers of deep action, even with normal porosity of the walls.

The nuances of applying the soil also depend on the base material. Drywall, for example, due to its high absorption, is processed under putty and after it. Otherwise, gypsum draws moisture from the finishing layer of the plaster.

Bottom line - the wallpaper disappears from it. Alkyd compounds are not suitable for drywall. PVA-based primers are acceptable but ineffective. The use of acrylic primers is recommended.

Universal priming rules include:

- Preliminary cleaning of the surface from litter, dust, stains of grease, soot, tobacco.

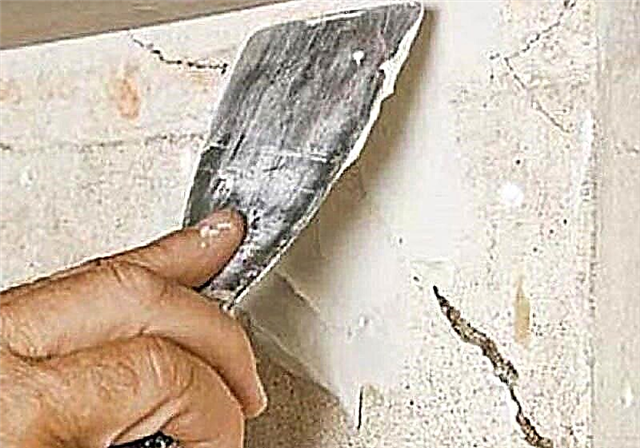

- Filling of large cracks and roughnesses in the base before priming, that is, puttying.

- Application of primer only to dry walls.

- Waiting for the complete drying of the previous layer of soil before applying the next.

You also need to glue the wallpaper, waiting for the walls to dry. You can check their readiness by fixing a piece of polyethylene on the surface with tape and waiting 2 hours. Condensation on the film is a signal for further drying of the substrate. If the polyethylene is dry, you can glue the wallpaper.

Primer price

Primer price for wallpaper depends not only on the type of primer, but also on its consumption. Predicted material costs are recorded on the packaging. Packing is of different sizes, for example, 5, 10, 25 liters.

If we consider 10-liter packs, universal primers cost about 200 rubles, acrylic - about 400, alkyd - in the region of 100-200, and deep penetration primers - 500 rubles. For 10 liters of specialized impregnation for wallpaper will have to pay about 380 rubles.

Partly, the primer price tag depends on the manufacturer. If his name is known, it has proved itself well, an extra charge is inevitable. The products of little-known firms, by contrast, are cheaper, even if they are produced abroad.

The need to use primers

The primer for walls under the wallpaper is available in bulk or in liquid form. It is pre-applied before the finish. Priming the surface is necessary for a number of reasons:

- the possibility of creating a monophonic coating,

- isolation of dust particles under a layer of composition,

- the ability to envelop pores - the primer allows you to get a perfectly smooth wall without cracks and chips,

- increase the reliability of setting the finish,

- ensuring the quality of fixation and adhesion of wallpaper,

- increasing the resistance of materials to wear, moisture and fungal environment,

- glue saving - it lays down in an even layer, since the wall becomes not so porous.

Advice! If there is mold on the wall, then after applying the soil with antibacterial properties, it will disappear.

Penetration rate

Standard compositions enter the surface layer by 2-3 mm. The deep penetration primer is distinguished by the ability to hit 5-10 mm, which is important for porous materials.

On a note! Concentrated saturated mixtures penetrate 2-3 cm, which allows you to create an even coating.

Release form

You can choose a high-quality primer for the wallpaper in the consistency:

- liquid. The composition is homogeneous, is applied immediately after opening the container, dries quickly,

- dry. The powder mixture is diluted with water according to the instructions.

Important! The proportions of materials can be found on the packaging.

Consumption

To qualitatively primer walls with an area of 1 m 2 you will need in average proportions:

- acrylic composition - from 50 to 100 ml,

- alkyd primer - from 100 to 150 ml,

- mixtures with a deep level of penetration - 100-150 ml,

- glue with a priming effect - 100-150 ml,

- specialized emulsion for liquid or non-woven wallpaper - about 200 ml.

On a note! The denser the material, the greater the consumption of impregnation.

The transparent primer does not change the shade of the wall surface. Covering pigmented primer for wallpaper allows you to get a pure white color.

Acrylic Emulsions

Universal and popular mortar for walls made of brick, plywood, wood or concrete. Acrylic primer is not suitable for ferrous metal structures. Its benefits include:

- fast drying period - in 6 hours,

- lack of pungent odor,

- ease of dissolution in water,

- glue consumption reduction.

Important! Acrylic protects the finish from mechanical damage.

Alkyd materials

Alkyd primer is suitable for applying to a surface made of metal, wood processing, chipboard and fiberboard from decay, compatible with glass. It removes rust, eliminates the likelihood of corrosion. Drying speed - from 10 to 15 hours.

Advice! Under the wallpaper, you should take the soil, which includes chromates.

Latex primer

If you care about the environmental friendliness of your home, focus on latex materials. The suspension is made on the basis of rubber juice, so it:

- increases elasticity, elasticity and resistance of wallpaper to compression,

- prevents moisture from reaching the surface,

- Suitable for loose and loose walls.

This type of soil is an expensive material, and the quality of the hitch with decorative trim is worse than that of acrylic.

Mineral Primers

Suitable for surface treatment of walls made of concrete, expanded clay concrete, brick and gas blocks. The base of the primer is cement, lime or gypsum, which can crumble if not properly diluted with water. The drying time of the material is 3-14 hours.

Perchlorovinyl solution

If repairs are started in the winter or late in the fall, this primer of the walls under the wallpaper is justified. The composition allows for a short time to prepare brick and concrete for decoration, is characterized by good adhesion and antiseptic characteristics.

Advice! Soil is toxic, so wear a mask when working.

Mixture Properties

If you need a specialized primer for walls for any wallpaper, but what to choose - there is no solution, pay attention to the characteristics:

- insulation. Resins, oils, adhesive components of the soil form a waterproofing film. Finished finish does not get wet even when washing,

- corrosion protection. Metal walls can be treated with a phosphating, passivating, tread mixture. They create a film or fill the pores with zinc dust,

- mold counteraction. This material serves to bond the surface and improve the quality of adhesion. It removes fungi or even eliminates them,

Important! Contactless solutions are not suitable for use before wallpapering.

Fluid finish

In terms of consistency and composition, liquid wallpaper resembles decorative plaster, but is made on the basis of cellulose or silk fibers.

High-quality processing of the wall will provide a white primer for liquid wallpaper or a completely transparent suspension. The material is superimposed in 3-5 layers - so spots will not appear.

Quartz primers require alignment with acrylic primer. This is necessary to reduce the risk of tearing or roughness, even laying of the material.

Advice! Control the color and consistency of the impregnation to make the finish look beautiful.

Emulsions for non-woven wallpaper

Qualitatively prepare the base will help a special primer for non-woven wallpaper:

- acrylic. Surface leveling is carried out with a composition diluted with water. It is applied with a brush or roller. The product has no smell, so you can not protect the respiratory system,

- alkyd. A white pigmented primer for wallpaper is the best option for a perfect finish. Stains may appear on a brown or gray suspension,

- latex. Due to the ability to envelop the pores, the emulsion provides crack repair, which reduces the amount of glue and improves the quality of adhesion of materials,

- special glue for non-woven wallpaper. The product must be diluted with water, adding it twice as usual. Glue is added, continuously stirring. The solution is infused for 10 minutes, then mixed again and evenly applied with a roller.

The work process begins with the preparation of the wall surface, then the soil is prepared, applied by the first layer, and after drying - the second.

Primer impregnation for material

The thick wood of which the walls are made can absorb moisture, warp or decay. Thin rails with poor-quality fasteners are deformed when exposed to water. Before wallpapering, the surface is treated with an antiseptic, then an alkyd primer for wood should be used, applied in 2-3 layers. Upon completion of drying, the base is painted and finished.

Plastered surfaces, walls made of brick, concrete, foam blocks are covered with mineral and silicate impregnations.

On a flat, high-quality basis, latex and acrylic aqueous suspensions can be used. They are inexpensive, economical to use and easy to apply.

Calculation of material consumption

To find out how much primer product for the wall should be taken, you need:

- Calculate total surface area.

- Multiply the number by 1.5.

Important! The manufacturer's instructions also indicate the amount of material per square meter.

Basic wall preparation

- Remove the old finish by dampening it with spray water. Scrape off the remains with a spatula, cutting off the dried-up areas with a knife.

- Check for residues of plaster or old emulsion, identify its density. The surface is sprayed with water, and then inspected for absorption speed.

- Inspection for the presence of fungus or mold - to remove them, use an antifungal primer for liquid wallpaper, non-woven or paper finish.

- Coating of low-porous walls with compositions with increased adhesiveness.

- Processing loose and porous substrates with deep penetration suspensions.

Advice! The primer is applied in several layers.

Primer application

To process the walls, you will need:

- Prepare a bucket for the mixture.

- Put a plastic masking net on 1/3 of the container - this way you can squeeze out excess primer.

- Shake the composition in a factory bottle or dilute it with water. Proportions are usually indicated on the label.

- Pour some liquid into the stain container.

- Dip the roller into the container, squeeze it on the textured platform.

- Coat the wall surface by rolling the suspension into a thin line.

- To process hard-to-reach areas with a thin brush, moving from top to bottom.

- Wait until the first layer has completely dried (the soil will be slightly sticky) and apply the second.

Advice! If the priming emulsion is not enough, you can dilute it with water 1: 2.

We prepare the walls for the wallpaper:

Starting to wallpapering, the basic basis must be processed. Any master will say that priming is a must. But people far from repair are unlikely to answer the question of why this is done. After all, there is no visible effect from this. And if you need to, then how to choose it? On the shelves of construction stores is just a frightening assortment of cans, cans and pails. We will figure out how to find a suitable primer for the walls under the wallpaper, apply it correctly, and what subtleties to take into account.

What it is

An odorless liquid, transparent or white, which glues the upper layers of the base, preparing it for further processing and improving adhesion to the following layers of finish. In its production, natural and synthetic materials are used: water, drying oils, alkyd and epoxy resins, polymers and dyes. Thanks to the water base, the solution penetrates into the porous base. Water evaporates, and the adhesive particles interconnect, forming a kind of frame that holds the base together. The grill of this frame allows air to pass through, so primers are used in all residential premises.

There are both finished products and dry mixes that are bred independently. The shelf life of the second is much longer. Many manufacturers offer concentrated anhydrous formulations that must be diluted with water before use. Do not use the concentrate in its pure form. This will not add strength to the base, but it forms a strong glossy film on its surface, which will be difficult to adhere to.

Do I need to prime under the wallpaper

The walls are not perfect smooth. They will always have roughness and roughness that can ruin the appearance of the finish. A primer comes to the rescue. It not only eliminates external flaws, but also improves performance:

- prevents cracking and shedding of the base,

- strengthens porous and loose surfaces,

- increases the adhesion (adhesion) of the wallpaper to the plane,

- prevents mold and mildew in the treated areas,

- reduces glue consumption during wallpapering,

- reduces moisture absorption

- maintains a favorable microclimate in the room without blocking the pores of the processed material.

By appointment

According to the tasks and stages of processing, they distinguish:

- for initial finishing - deep penetration (primer),

- for final finishing - adhesive, dyeing and moisture-proof.

Deep penetration soils strengthen the workable base, penetrating 10 cm deep. They are used for the primary processing of concrete, brick, drywall, foam and aerated concrete surfaces. Consist of water, acrylic, polymers, silicone and latex additives. Antiseptics are added to some formulations to prevent mold and mildew. For heavy varieties of wallpaper, it is advised to use this particular type. However, they are not advised to use it for materials that poorly absorb moisture.

Primer Ceresit CT 17 deep penetration

Adhesive penetrate the base by 2-3 cm and improve its bonding with the following layers of finish. They are used for poorly absorbing surfaces, such as smooth concrete or areas painted with oil paint. The most famous adhesive primer is concrete contact (concrete contact, concrete contact). Its composition includes quartz sand, due to which a rough film is formed on a smooth plane, similar to sandpaper. Heavy types of wallpaper, such as embossed vinyl on a non-woven fabric, fit very well on it. To visually identify the treated area, manufacturers began to pigment the solution. For example, the most famous concrete contact from Knauf is pink.

Primer Prospectors Concrete Contact (20 kg)

Moisture-proof are used in rooms where the humidity level is above average, for example, a kitchen. Wallpaper for such rooms is chosen special, resistant to dampness. So that they do not fall off and do not deform, before gluing, the base is treated with moisture-resistant soil. It passes water vapor, but does not form condensate.

Staining is used before gluing non-woven wallpaper for painting. In this case, not only the plane plane of the walls is important, but also the uniformity of the shade. Dark spots will be clearly visible under a thin layer of non-woven fabric. For these cases, they take a pigmented primer for wallpaper. It gives the surface a uniform color.

Experienced craftsmen usually use both types of soil: for initial and final processing.

In terms of composition

Soils, which are used for repairs in residential premises, are divided into acrylic, latex, mineral, alkyd, glyphthal.

Acrylic or water based are universal. They are used for concrete, brick, wood, plastered, plasterboard materials. They can not be used only for metal. They are odorless, which is convenient when working in an apartment. After processing, the material remains breathable. The drying time is four hours. Acrylic is considered an ideal material in combination with vinyl or non-woven wallpaper.

Latex reinforce loose collapsing structures, have excellent waterproofing properties. They are used for concrete, drywall, plaster, wood and its derivatives. It is based on synthetic latex, which has all the properties of natural: elasticity, strength, water resistance, and resistance to stretching.

Minerals are suitable for the processing of concrete, brick, gas silicate blocks, plaster. They are composed of lime, gypsum and cement. Because of their consistency and color, they are called “cement milk”. Most often used for primary processing and leveling the base at the beginning of repair. Drying time from 2 to 24 hours (depending on the manufacturer, the thickness of the layer and the processed base).

It is better to choose a primer and basic finishing material, such as putty, of the same manufacturer.

Alkyd specialize in wood, chipboard, OSB and fiberboard. The processed material becomes more loose, which provides a more tight grip with subsequent finishing. Drying time 10-16 hours. It is not recommended to use for plaster and drywall.

Glifthal - designed for metal and wood. Before applying, thoroughly clean the surface from rust. They dry for about a day.

According to the wall material

For untreated concrete foundations, it is advised to take mineral formulations. One to three layers are applied depending on porosity and friability.

What primer is needed for liquid wallpaper? Primer before applying it is necessary. This will even out and smooth out minor defects of the base, provide good adhesion to the plane. In addition, this will reduce the absorption of moisture, and save the consumption of the solution. Acrylic universal and adhesive compositions are best suited for these purposes. The former strengthens the upper part of the base, the latter create a rough film on it, on which the liquid finish perfectly fits.

Drywall must be primed. Otherwise, during the next repair, the wallpaper will have to be removed with your own hands along with the putty or the top layer of the panels. Drywall is treated with acrylic impregnation. The first time before puttying, the second - before gluing.

Mortar consumption rates

Soil consumption is usually indicated on the packaging per 1 square meter of plane. It depends on the absorbency of the substrate and the type of soil.

| View | Consumption rate, gr | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete contact | 350 | |||||||||||||||||||||||||||||||

| Deep penetration | 100-200 | |||||||||||||||||||||||||||||||

| Universal acrylic | 100-150 | |||||||||||||||||||||||||||||||

| Latex | 100-150 | |||||||||||||||||||||||||||||||

| Mineral | 200-300 | |||||||||||||||||||||||||||||||

| Alkyd for wood | 100-130 | |||||||||||||||||||||||||||||||

| Gliftalova |

| View | Surface | Time |

|---|---|---|

| Concrete contact | everything | 6 h |

| Latex | everything | 40 min |

| Universal acrylic | concrete | from 1 to 3 hours |

| drywall | 12 h | |

| brick | from 6 to 8 hours | |

| plaster | 2 to 4 hours | |

| Deep penetration primer | everything | 24 h |

| Mineral | concrete | from 2 to 6 hours |

| Alkyd | tree | 10-12 h |

| metal | 10-15 h | |

| Gliftalova | metal | 24 h |

The main mistakes made during drying:

- drafts - open windows and doors will provoke uneven drying,

- the use of a hairdryer or heat gun - the outer layer of the mixture dries faster than the inside,

- temperature differences - the lower the temperature drops, the slower the material dries.

How to store the solution

Shelf life depends on the composition of the mixture. The manufacturer indicates it on the package. At the same time, compliance with storage conditions is emphasized. The liquid is stored in the original container in a closed form. If the canister was opened and poured into another container, the shelf life is reduced. Storage at subzero temperatures is not allowed. It is necessary to protect the tank from direct sunlight and heating appliances. A concentrated solution diluted with water is best used on the same day. It makes sense to breed not the entire package, but the desired volume.

Usually primers are stored for longer than the period specified by the factory without loss of quality. Unsuitable for use can be determined visually. Lumps appear in the composition, it exfoliates and a dense precipitate sinks to the bottom. Stains or film appear on the surface. The strong marsh odor is also an indicator of the unfitness of the product.