In the life of a modern person there are many different rubber products. This material has a lot of advantages - it is flexible, waterproof, resistant to atmospheric influences. Meanwhile, it is prone to deep scratches and cuts. For this reason, glue for rubber is very popular among buyers. It is important that the purchased composition possess the necessary properties. The buyer should know that he will not fail at the most crucial moment.

It should be noted that today on the construction market a rather extensive range of materials for repairing rubber is presented. The main properties of such products directly depend on their purpose, so you should not assume that any rubber glue is universal. This is not true. Due to inappropriate use of the adhesive, the result of the work may disappoint you - it will be very different from the manufacturer stated in the instructions. Therefore, glue for rubber should be chosen very carefully.

Types of Rubber Adhesive

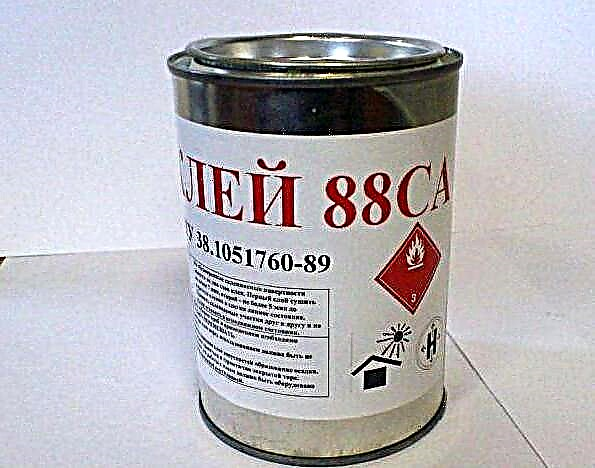

These adhesives are divided according to their purpose - industrial and domestic. It is clear that industrial glue is used in production, is produced in large volumes, and it is applied using special equipment. Such a composition is not sold in retail stores, as it is designed for bulk orders. This includes rubber glue 88, 88H, 88CA.

Such compositions are used in construction during the installation of sealing and finishing materials, in the automotive industry for bonding rubber products, in the furniture and shoe industries. This product is suitable not only for connecting rubber products, but also for combining rubber with metal, cardboard, plastic or wood.

As a rule, when working with rubber, textiles, cardboard, leather, paper, resin adhesives are used. These are viscous solutions based on plant resins in water or in organic solvents. Such compounds are called rubber and gum adhesives.

Rubber glue is a 5-7% solution of natural rubber in pure gasoline. Today, it is often replaced by compositions of synthetic rubber. The most famous and popular representative of such mixtures is 88CA. This is a colloidal solution of rubber and phenol-formaldehyde resin, mixed with nefras and ethyl acetate. It is used for bonding rubber and concrete, glass, wood. This glue is perfect for mounting linoleum on concrete or wood, gluing foam and foam between them. The product is no less effective for gluing them to concrete or wood. This glue is also suitable for working with textile materials and leather, for shoe repair.

Characteristics of 88 CA glue:

- glue is completely waterproof, does not break down from moisture,

- does not create toxic compounds with air,

- not destroyed at temperatures from -500 to +700 degrees,

- does not violate the surface of products, does not interact with them,

- does not cause corrosion of metals, protects wood from rotting and parasites, provides waterproof properties to cardboard.

The price of the product is 230 rubles (liter).

Rubber glue 4508

Another adhesive based on rubber is 4508. It also has excellent water resistance, elasticity of joints and high stickiness. Such a composition is used in the textile industry, in the manufacture of various rubber products, special protection suits, rubberized fabrics. The increased elasticity allows it to be successfully used in the repair of PVC boats, leather goods, fishing suits.

This is a two-component composition, so it needs to be prepared before work. The glue burns well, so it is necessary to protect it from sources of open flame. The price of the product is 160 rubles per 200 ml.

Grade A Rubber Adhesive

Now we will present you rubber glue from natural rubber, which is one of the most common in everyday life. The composition of grade A is used to repair car cameras, connecting rubber with paper and cardboard, leather products. This product is very easy to use, has good specifications and an affordable price. The glue dries quickly and perfectly holds the joint for a long time. Price - 135 rubles per kilogram.

Features

Rubber glue based on rubber is widely used in many industries and spheres of human activity. It can be used to work with a large number of materials.

Rubber glue remains elastic even after complete hardening. This is its main feature, for which it is appreciated and chosen for working with elastic materials. In the solid state, it resembles rubber as much as possible.

When choosing glue, you need to pay attention to the composition. It should be as close as possible to the glued parts. Some manufacturers do not use natural rubber, but synthetic. And also each of them uses his own recipe.

In most cases, the formulations are unique. The characteristics of the final product, operational properties and characteristics strongly depend on the recipe used.

Composition

In the domestic market there are a large number of rubber glue. You can choose transparent or industrial, elastic or very durable, for different purposes and materials. In any case, all of these substances will have a similar composition. Rubber glue is a natural rubber that is diluted in a solvent. Therefore, when speaking of a rubber product, rubber adhesive is always implied.

As a solvent, substances such as:

- compounds with chlorine

- aromatic

- ethyl acetate with nefras.

The first two options are toxic and are used in a minimal amount. The latter solvent has received much greater use. Water-based latexes are used to reduce fire hazard and toxicity. Such a composition, although it is safe, but it is characterized by less stickiness.

Glue, which is made from natural rubber, may contain resins and polystyrene with a low molecular weight structure. Their quantity in the mixture is limited, otherwise the elasticity of the seam is lost.

The role of hardeners is performed by agents that are selected according to the rubber used. In most cases, metal oxides and sulfur are used. Amines are well suited for cold vulcanization. And also in the composition of the rubber glue contains plasticizers. Mineral oils do an excellent job with this role. The stabilizer is ethanol, which prevents gel formation. Carbon black is used as a filler.

The composition, as can be seen, is complex and diverse. Each manufacturer has a unique recipe that can not be divulged.

Rubber glue production is regulated by GOST. A mixture that meets these standards is the highest quality.

The separation of rubber glue into types is carried out according to two main characteristics: the amount of solids and the composition of rubber.

The production of rubber adhesives is carried out in accordance with GOST 2179-78 and TU. According to these regulatory documents, the amount of solids can be from 6 to 8% and from 8 to 12%.

The product belonging to the first category corresponds to brand A. Products from the second category are assigned brand B.

Depending on the composition of the rubber, several types of adhesive are distinguished.

- Natural rubber based material may not be used in all cases. For example, for some industries, the use of such glue is unacceptable. The reason lies in the low resistance to the impact of aggressive conditions. And also the natural component is not able to withstand high temperatures.

- Chloroprene material incorporates divalent metal oxides. Such glue is more reliable, durable and resistant when it comes to the effects of aggressive factors. For working with metal, glass, plastic and wood, it is better to choose just such a substance.

- Nitrile butadiene rubber makes the mixture waterproof, which determines the scope of its use. Although sulfur is present in the composition, the formulation also suggests the presence of tiurams.

- Silicone rubber allows you to create a special glue. To solidify, tetrabutoxylan is required. Such glue is used to work with homogeneous rubber.

- Styrene butadiene rubber serves as raw material for the manufacture of industrial rubber glue. It is characterized by weak bonding abilities, therefore it is used most often for the production of adhesive tape.

These are not all varieties of rubber, which is used to create a rubber substance. Other options are less common, and the use of such mixtures is limited.

It is worth familiarizing yourself with the brands that are available to the Russian user:

- A great rubber sealant is produced by a Russian manufacturer. This brand is well known to everyone - 88 N. This glue is applicable to many materials; it is highly reliable and durable. It is perfectly diluted with benzene, resulting in a homogeneous mass.

- Glue brand 4508 widely used for gluing rubber and textile technical products. It requires careful preparation of the workspace.

- Under the brand name Plasti Dip is a paint based on rubber. Such material is used to cover the external parts of the car, which helps protect it from external factors and improve the appearance.

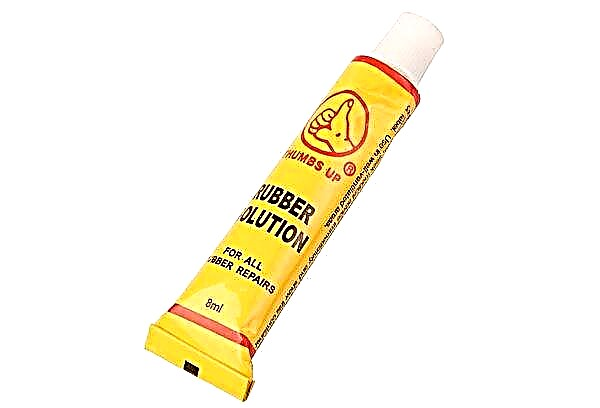

- In the shoe industry is often used rubber glue Rubber Cement. Parts stick together weakly and even after a while they can be easily disconnected. Such qualities are valuable when attaching external parts to shoes and fixing the lining.

- Glue 88 CA created on the basis of colloidal rubber and phenol-formaldehyde type resin. These components are mixed with nefras and ethyl acetate. The glue is very strong, reliable and durable. It is widely used during repairs and even in the construction industry.

Specifications

A large selection of rubber adhesives has determined an extensive set of technical characteristics that may be inherent in a particular product. It will not be difficult to choose just the option that will best meet the user's requirements.

- Waterproof glue especially relevant when repairing rubber boats, leather goods and shoes. Another composition is not suitable for this work. Need adhesive material exclusively with a waterproof effect.

- High strength adhesive able to withstand aggressive operating conditions. Such materials are used in the field of car repair and construction. It must be handled with care, since it will be difficult to remove the dried adhesive solution and redo the work.

- Quick-drying rubber glue reduces the bonding process of materials. But with such material it is difficult to glue large parts. Most rubber compounds dry quickly when heated.

- Stretch seam - This is the main feature that is characteristic of the rubber adhesive material. This characteristic allows you to glue soft materials, while maintaining their structure. When dried, the adhesive becomes like rubber: soft, flexible, pliable and durable.

- Oil resistant glue based on rubber is necessary for working with petrol and oil resistant rubber products. An example of such mixtures is leukonate, B-10 and KR-5-18.

Many manufacturers produce universal formulations that combine all of the described characteristics or most of them. When choosing glue, it is necessary to carefully study its technical characteristics and operating conditions that it can withstand.

Appointment

Rubber glue can be used to glue almost any material. For household needs, brand A adhesive mixture is most often used.. With its help, you can repair cameras made of rubber, leather products, connect rubber with paper surfaces. And also such glue can be used to fix carpet, linoleum and other floor coverings. There are separate varieties of rubber glue that are suitable for metal and glass.

For industrial purposes, glue 4508 is most often used.. It is suitable for textile coatings, repair and production of rubber products, vacuum products. For the organization of floor coverings, it is customary to use polyurethane adhesive. It is used for rubber crumb and tile. Such a tool is appreciated for its high resistance to atmospheric effects and mechanical damage, repeated friction, high pressure and many other loads.

Manufacturers

It is well known to the Russian user glue "Moment". This is truly the best option for home use. It has an extensive scope of use and makes it easy to solve most of the tasks that may arise in everyday life. The only drawback is the quick hardening of the glue, which makes the tube disposable. Even after tight closing, the glue in the tube will still harden and become unsuitable for further use.

Company "Novbytkhim" from St. Petersburg has an extensive production of household chemicals and paint products. Among such a wide assortment there is also a rubber special adhesive brand 88-HT.

Ecoline company produces a range of rubber compounds. Among such an assortment, it is easy to choose the right option for any job. Products are produced in various volumes, which is convenient for the user. Stamps from this manufacturer are often purchased for various industries.

Instructions for use

You can choose the most expensive and reliable glue, but the desired result will not be achieved. The reason will be hiding in improper use and non-compliance with the instructions. Therefore, it is worth considering the rules for using rubber glue at home.

Gluing can be done in two ways:

- Cold gluing performed at room temperature. In this case, the complete drying of the seam will have to wait several hours or even several days.

- Hot gluing involves the use of temperatures from +70 to +160 degrees. At the same time, the drying time of the seam is significantly reduced and usually is only a few minutes.

Before using the mixture, you will definitely need to make a quality and thorough preparation of the workspace. The essence of preparation is to perform the following steps:

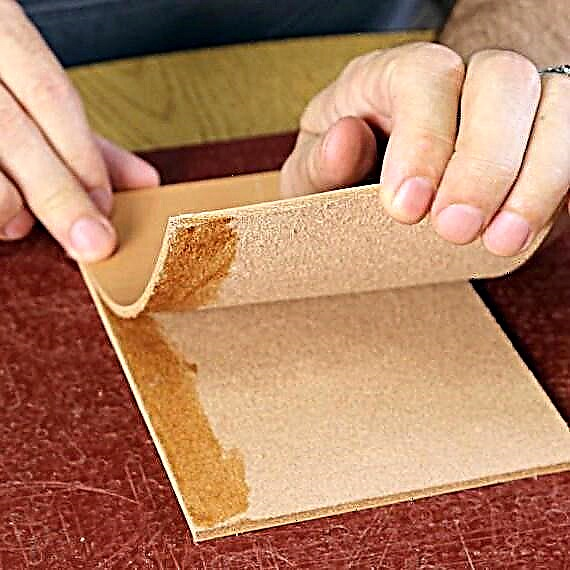

- abrasive treatment, which fine sandpaper is perfect for,

- thorough degreasing and removal of complex contaminants,

- surface treatment with a special cleaner that will remove dust, including the smallest particles.

Such preparation will provide better bonding of surfaces and increase the reliability of the seam. And also when working with any rubber glue, it is necessary to observe such rules as:

- all rubber adhesive mixtures are flammable, therefore it is strictly forbidden to work near an open flame source,

- instructions for use must be observed to the smallest nuances, it is impossible to deviate from the manufacturer's recommendations under any circumstances,

- when performing hot gluing, it is convenient to use a building hair dryer, which will allow you to safely bring the glue temperature to the desired temperature in a short time,

- hot gluing is performed only in the open air, since the composition can emit fumes harmful to humans.

Important! For different types of adhesive rubber compounds, different instructions for use can be applied. All the necessary information is on the packaging, so you should carefully study it before starting work.

Rubber glue can be prepared with your own hands. There is nothing complicated in this.

You need to proceed as follows:

- finely chopped rubber must be diluted with nephras,

- the mixture is placed in a water bath and heated to +50 degrees,

- to completely dissolve the rubber, you will need to wait 2 hours,

- in a mixture that will resemble sour cream, you need to add 4% sulfur and 1% magnesia.

The preparation of the mixture is completed. The final product is waterproof, durable and reliable, suitable for working with almost any material.

Rubber material properties

Rubber glue is a rubber-based product dissolved in special substances. As it hardens, the product retains its elasticity. Therefore, it is permissible to use it for fixing materials that have a different texture.

The composition often introduces additional components that improve the characteristics of the adhesive:

- polymer resins

- vulcanizing components

- plasticizers

- crosslinking type components.

There are quick-drying substances on sale. The compounds are used in everyday life and industrial purposes. A quality product fills even small holes and voids, penetrating into any cracks and seams. Thanks to this, the product is firmly fastened.

The characteristics of glue for rubber include the following:

- excellent adhesion

- high strength of the seam,

- the absence of destruction over a long period of operation,

- resistance to temperature influences, influence of chemicals and aggressive factors,

- joint flexibility

- transparent consistency

- lack of pungent aroma.

Individual formulations are considered heat resistant. They are able to withstand strong heat. All rubber adhesives are water resistant. They prevent moisture from entering the bonded area.

Glue 88 (CA, N)

These adhesives are often used in construction. They are used for the installation of finishing surfaces. Also, the compounds are often used in the automotive field - with their help, rubber elements are fixed. Substances used for furniture and shoes. The composition helps to glue rubber fragments or fix them on paper, wooden or metal surfaces.

Glue 4508

This tool is highly moisture resistant. It is considered elastic and has a high stickiness. The composition is used for the manufacture of textile products. They are glued with special suits or rubberized materials. Means perfectly glues boats. It is also permissible for them to fix other PVC products.

Moment Rubber

This substance is characterized by high resistance to moisture. It is considered sticky and provides elastic seams. The tool is used for the manufacture of textile products. It is used for the production of rubber items. High elasticity allows the use of the composition in the repair of boats, leather products.

The composition is considered two-component. Therefore, he needs preparation for work. The glue burns well, because it should be kept away from sources of fire.

Radical

This glue is considered high-strength and has good elasticity. The composition is able to withstand high blood pressure and severe loads. The radical tolerates the influence of low temperatures and behaves well even in sea water. The glue is suitable for repairing kayaks. It is also used for gluing rubber boats.

Metal

Sometimes you need to glue materials that are difficult to fix. These include metal and rubber. Usually the adhesive does not harden on smooth metal, but rolls down. For bonding such materials using substances TRS 4004, 103 88-HT, Leikonat, BF-2.

To achieve reliable fixation of fragments, it is necessary to properly prepare the surface. First of all, it is recommended to clean the metal from rust or oils. After which it should be degreased. It is recommended to create a rough coating on rubber and clean it with a degreasing compound.

The surfaces should dry out, after which they should be covered with adhesive and wait a quarter of an hour. Then apply glue again and wait for the film to appear - it will take 10 minutes.

In conclusion, it is worth fastening the fragments and pressing them with effort. If possible, glued fragments should be warmed up and left to dry. The duration of this process depends on the composition.

For fixing rubber with PVC it is worth using glue 4508. This composition is highly sticky and resistant to moisture. It helps form an elastic seam and is often used to repair boats.

Instructions for use

To tightly stick a vacuum or other rubber product, it is worth following the instructions for use of the substance. The use of such a composition is prohibited in rooms with a temperature of less than +5 degrees.

To increase the efficiency of fixing parts, it is recommended to prepare the surfaces before applying the adhesive composition. To do this, they are cleaned of impurities - dust and pollution.

Before applying the composition on the surface, it is recommended to walk with abrasive material. This increases the adhesion of the elements. To remove foreign objects, use a soft lint-free cloth. To cope with stains of oil or fat, degreasing agents such as acetone are suitable.

Apply the substance with a brush. If the mixture is very thick, a spatula is recommended. Its shape and width are chosen individually. The layer thickness should be at least 2 millimeters. Usually it is selected taking into account what details are planned to be fastened. So, for fixing rubber shoes or a spoon, 1 millimeter of glue is used. Gauze is laid on top, pressing it with a spatula. This layer acts as a reinforcing element.

After a quarter of an hour, it is recommended to again apply a layer of glue. To improve the connection, all elements should be placed under the press and left for a couple of hours. Excess glue is recommended to be removed. The ultimate bonding performance is achieved after 1-2 days.

Useful Bonding Tips

In order to glue a rubber product in a quality manner, it is worth following the basic recommendations of specialists:

- Individual substances become thick during prolonged storage. To avoid this, it is worth checking the expiration date before buying.

- Before fixing the elements, it is recommended to clean the surfaces of dust and dirt. Of no small importance is the degreasing of the elements and thorough drying.

- The adhesion characteristics of the material increase significantly, if before applying the composition to clean them with sandpaper.

- First, it is recommended to sand the surface, and then degrease. It is best to use a solvent that evaporates easily. This category includes gasoline and acetone.

- The substance is recommended to be applied with a brush. For a dense mass, a spatula is suitable.

- The thickness of the adhesive layer must be at least 2 millimeters.

- If spots or excessive glue appear on the surface of the product, it is recommended to remove it. This is done with a knife or spatula.

- It is recommended to keep the glued area under the press for several hours.

Low moisture parameters slow down the drying of the adhesive. A good composition sets in half an hour. Finally, it freezes in 2 days. Today, there are many effective adhesives for rubber. To achieve good results in the fixation of products, it is necessary to properly prepare the surface and clearly adhere to the instructions for applying the substance.

Stamps and cost of rubber glue

Several types of adhesive are known. To make the seam strong and elastic enough, you need to choose the right bonding agent.

- Rubber glue88n Russian production. Its cost ranges from 200 to 400 rubles per kilogram. It glues rubber products, as well as any other materials, qualitatively and for a long time. Sometimes it is diluted with benzene until a homogeneous consistency resembling thin sour cream is obtained. A rubber part is lubricated with a mixture, allowed to dry for 3-5 minutes, then glue is applied again on both surfaces to be joined. After 5-6 minutes, the parts are firmly connected and dried under a press.

- Rubber gluebrands «A»Made of natural rubber. It is used when sewing clothes, leather goods, shoes, for bonding rubber and woven materials. It creates a high-quality and durable connection, it is very convenient to use. Rubber glue of grade A costs up to 50 rubles per pack of 50 ml.

- «Rubber glue 4508»Great for bonding rubber technical products and textiles. The cost of this composition is in the range of 100 rubles per 100 ml. When glue gets on paper, the rubberized tissues of their parts become sticky. Therefore, the adhesive composition is used to restore the chambers, boats from rubber, wading boots. When treated with glue 4508, a plastic seam is obtained, which is characterized by durability, water resistance and resistance to environmental influences. When using it, one must strictly follow the recommendations on the packaging. The surfaces of the parts to be glued must be thoroughly prepared. Often there is dust on the rubber, particles of various substances and oil. They will have to be removed using special tools.

- Rubber glue «GOST 2199-78". Used for gluing cardboard, leather, fabric and rubber parts. This rubber glue forms an elastic bond, almost leaves no residue, does not require the removal of grease from surfaces. The adhesive mass is applied evenly on the parts. After 15 minutes, make a second layer of glue, hold for 2 minutes and firmly press each other parts of the product. The final drying of the glue is achieved in a day. It is produced in packages of 1, 2, 50 and 200 kg. Often used on an industrial scale. In terms of quality and reliability, such rubber glue far surpasses popular superglue. It is not difficult to use, comfortable in transportation and allows you to quickly and accurately perform repair work.

- Liquid rubber Plasti dip. This is a rubber based paint. It is an indispensable tool for coating, protecting and improving the appearance of the car. The composition is applied to the body. Liquid rubber coating gives the surface excellent shock and anti-slip properties, is resistant to moisture penetration, ultraviolet radiation, temperature extremes, and has significant elasticity.

- Rubber glue Rubber cement. It is characterized by the fact that glues leather parts not tightly. Even after the lapse of time, the glued surfaces can be disconnected. It is used by shoe masters to fasten the outer part of the shoe and lining. The glue has a sticky viscous consistency, the density is different. Superimposed on the surface of both parts, left for some time to absorb. Then the details are pressed against each other. Glue is very convenient to handle large surfaces.

Boat Repair Adhesive

Despite the fact that modern boats (inflatable) guarantee reliability and safety in use, sooner or later they will still need repairs. In our article, we will consider some types of adhesives that are currently on the Russian market. Good reviews get:

- “Rogneda” - inexpensive rubber glue, the price of which ranges from 275 to 320 rubles per 900 ml,

- Super-NN (690 rubles per 1 liter) in combination with Izur-021 additive.

Fishermen are satisfied with the quality of mixtures working on the principle of cold welding, especially with regard to plumbing compositions of this type. These include glue for boats GRIFFON UNI-100 or Tangit PVC-U.

The composition of “Loktayt Super Fast” very quickly sets. With it, in five to seven minutes it is quite possible to fix the boat in the field. Nevertheless, this product also has a drawback - fast bonding, as a rule, is characterized by uneven bonding over the entire area. Price - 91 rubles. (15 g).

Not bad proved themselves in the repair of boats (especially when heating the composition) Russian adhesives "Moment-gel" and "Moment-crystal." These are quite popular compositions that can be purchased at any hardware store.

How is glue applied?

Before gluing, the surface must be degreased and cleaned of dirt. You can use acetone. It will help not only to clean well, but also to soften the rubber structure a little (though not for long). Bonding is best done in several stages.

Necessarily need a primer layer that will allow the glue to set better. In addition, to improve the quality of work, it is advisable to use technical hair dryers. With their use, the compound warms up (to a temperature of 60 degrees). Never use open sources of fire for this.

To smooth wrinkles and squeeze out air bubbles, a heavy and dense roller will do. The joints at the time of gluing should be pressed down with some kind of heavy object.

Clay "Moment"

This glue is well known to many Russians. Moreover, if you ask about what is the best rubber glue, many will answer that this is “The Moment”. This is the most famous and most common composition in our country, which has been in constant demand for many years. Using this glue, you can connect almost any material.

Rubber glue "Moment" is intended for bonding foamed and hard rubber. In addition, it reliably combines rubber with other materials: rigid PVC, concrete, wood, cardboard, metal. The product provides very high strength, reliability, elasticity, water resistance and durability of the adhesive joint.

It is suitable for any home repair. Nevertheless, it is necessary to say about the drawback (the only one) - the glue dries quickly, so the tube can be considered disposable. If you do not completely use it up, the remainder will certainly dry up. A tube of 125 ml will cost about 102 rubles.

For rubber crumb

Modern rubber crumb coatings, which are made using seamless technology or are assembled from tiles, paving stones, as well as crushed rubber canvases, have proven themselves as durable and reliable options for forming the top layer on sports and playgrounds, tracks.

Reliability and quality of such a coating are determined not only by the properties of the rubber itself, but also by the quality of the bonding materials used in the manufacture of tiles, paving stones or mats, as well as laying them on the surface. Glue for rubber coating can be of two types:

- bitumen rubber mastic,

- polyurethane adhesive.

The latter option is a homogeneous liquid composition. It is colorless or whitish. Such products have varying degrees of viscosity. Polyurethane adhesive for rubber crumb is produced in two versions: one-component and two-component.

GOST on guard of quality

Today, the production of glue is carried out in factories using high-precision equipment.The composition of the product includes complex inorganic and organic elements. They are processed using modern technologies, which allows to obtain high-quality rubber glue. GOST 2199-78 provides and records the technical characteristics, composition, and safety standards of the product.

In addition, it establishes range standards for important parameters and values that all manufacturers operating in Russia must comply with. Products that do not satisfy at least one norm are not allowed for official sale. Therefore, do not be shy to ask the seller for permission to conduct trading activities and a quality certificate.

Key Features

This type of glue is often called liquid rubber, because it is made from natural rubber - a natural resin with powerful adhesive properties. Instead, synthetic resins can be used in the production of the substance. The rubber component for the production of glue is diluted in chemical solutions, depending on the brand and the exact type of product they vary. As solvents, as well as fillers in the rubber glue may be present:

- aromatic hydrocarbons

- chlorine compounds

- ethyl acetate mixed with nefras,

- polystyrene

- artificial latex

- pitches

- metal oxides

- amines

- sulfur,

- stabilizers - ethanol, diethylamine.

As plasticizers that improve the properties of glue, mineral oils, phthalates, lanolin, and carboxylic acid esters are introduced into the composition. In general, each manufacturer develops its own formulation of rubber glue, reducing or increasing the share of natural rubber in it and adding more and more new substances. In any product there is always a minimal set of components - a crosslinking agent, a curing agent and a solvent.

Glue can connect a variety of materials, apply it for domestic needs, at a construction site, in repair. They are repairing bicycle chambers, rubber boats, leather products at home, using it for shoes, closing holes, and defects. It is also possible to fix linoleum, carpet, and other floor coverings with this glue. Some types are permissible to work even on glass, tile, metal. Industrial compounds are used for coating rackets for table tennis, textiles (for example, gloves), vacuum products, in the manufacture of furniture, auto parts.

After hardening, the adhesive in appearance and properties becomes very similar to rubber. The tool is transparent and opaque, which must be considered before buying. It remains elastic even as it cures, for which it is appreciated by the craftsmen. Cons of rubber adhesives also have:

- not too aesthetic-looking glue line,

- unpleasant odor due to the presence of solvents,

- the need for good ventilation due to toxicity,

- difficulties with application

- the appearance of burns on the skin during sloppy work,

- risk of damage to instruments after the end of the process or difficulties with their washing.

Properties and specifications

The difference between rubber glue and other adhesive compositions is that it forms a seam that preserves plasticity. This product resembles elastic silicone sealants, which after drying also remain semi-solid, like raw rubber, due to which they do not crack during operation. The average viscosity of a VZ-246 viscometer for rubber adhesives is 10–40 seconds.

Rubber based adhesives have high tensile strength (from 1.09 MPa). And special high-strength compounds withstand the most severe loads, they are used at a construction site, in car repair. Most adhesives are waterproof, therefore they are suitable for repairing products that come into contact with moisture and even stay in water for a long time - boats, shoes. There are petrol and oil resistant products on sale that are insoluble in petroleum products (for example, adhesives of the KR-5-18, BR-10 brand).

On sale you can find quick-drying rubber adhesives, the curing of which occurs more quickly than with conventional formulations. Most often they are used in emergency work and in large-scale repairs, so as not to spend a lot of time drying. Universal adhesives combine all the basic properties of the listed tools:

- work at -50 ... + 70 degrees,

- water resistant, oil resistant,

- elastic

- Do not harm base materials.

Cold

This method practically does not differ from gluing products with conventional adhesive compositions. The process is carried out at room temperature. After applying the adhesive with a thin layer, wait 20 minutes, repeat the procedure, then connect the parts. Next, leave the subject to dry completely (from day to 2-3 days).

The choice and technology of work with glue for rubber

For repair or production of products, it is necessary to choose high-quality rubber glue. The more flexible the finished structure will be, the more flexible the composition should be. It is also important to take into account the humidity and operating temperatures of the product, the subsequent load, the structure of the materials (hard, soft, porous). Glue based on rubber should not harm the main material, show chemical aggressiveness to it.

The subtleties of the process

To reliably glue two surfaces or seal a defect, you need to make sure the glue consistency is optimal. Usually it thickens when stored improperly or when it expires. If in the second case it is better to discard the composition, then in the first you can dilute it a little. How to dissolve too thick glue? Nefras or benzene are usually suitable, which are added until a homogeneous mass is obtained.

Other useful tips when using glue:

- the temperature in the room should not fall below +5 degrees, otherwise the speed of solidification of the composition will sharply decrease, as well as the quality of the adhesive joint,

- rubber compounds are flammable, work with them is permissible only with careful observance of fire safety rules (it is forbidden to be near any sources of fire),

- deviate from the manufacturer’s instructions, it is impossible to reduce the exposure time of the adhesive joint to operation,

- for hot gluing, it is most convenient to use a building hair dryer, which very quickly heats the glue to the required limit,

- with hot bonding, harmful fumes are intensely released, so you can work only with good ventilation and wearing a respirator.

Surface preparation

When preparing, before gluing, remove any dirt from the products. It is recommended to sand smooth materials (sandpaper), this will help strengthen the adhesion of the adhesive to the base. After that, both parts must be degreased before gluing; for this, they must be wiped with alcohol, acetone or another rapidly evaporating liquid. Surfaces must be completely dry before work.

Glue application

Thick adhesives are applied with a small spatula, more liquid - with a brush. The thickness of the adhesive is about 2 mm. After applying it to 2 layers, immediately press the parts against each other or heat the glue or allow it to dry slightly in air - depending on the manufacturer's recommendations.

When repairing a boat, a thinner adhesive layer (1 mm) is made, then a piece of gauze is applied, another layer is applied, and only then a patch is attached. The glue that has come out is immediately removed with a knife, spatula. The product is aged 1-2 days or more, preferably in a vice or under pressure.

How to choose a glue composition

Select rubber glue based on the following conditions:

- thickness and size of rubber, its susceptibility to abrasion,

- ductility or stiffness of the material to be bonded,

- humidity and temperature conditions

- external qualities of the finished product,

- chemical composition of glue.

When the requirements and wishes for the resulting adhesive seam are met, the work will be performed efficiently.

Rubber glue is a universal means of repairing various products. With it, at home you can easily restore the integrity of damaged things, and they will last a long time.