Do you like to grow crops on your own on your own, but is it not always possible to constantly maintain optimal temperature inside a greenhouse or greenhouse? Then it was for you that a device such as a thermal drive was created. With its help, the automatic ventilation of the greenhouse is ensured when the temperature in it is increased to certain indicators.

What is a thermal drive?

The thermal drive carries out work autonomously, with its help it is possible to get an excellent crop. During the day, the weather can change several times, as a result, without this device, gardeners have to independently maintain the necessary temperature in the greenhouse by opening and closing windows and windows.

Well, if you go a couple of steps to the greenhouse, and what if it is located behind the site - do not run. The thermal drive mechanism is triggered to open at a temperature of 22 ° C, in models with a door closer the window or door is closed at an average temperature of 30 ° C.

Key device features

The thermal drive can be used not only during the growing season, but also in the cold season. In this case, the device is installed on the heating system, and its main task is to maintain a certain temperature of air and soil. The mechanism is operated by special sensors. In the warm season, the thermal actuator provides timely ventilation of the greenhouse or greenhouse, opening and independently closing windows and doors.

Types of Thermal Actuators

The device designed for installation on the door is a complex mechanism equipped with a door closer.

Thermal actuator for window leaves

Models for window leaves carry out their work in one plane. Universal thermal drives, which can be installed both on the door and on the window, constitute a separate category — they are considered the most popular.

Equally effective is the use of several models when mounting them in different places of the structure. This scheme allows the formation of through air flow due to natural traction.

And 2 types differing by the principle of work:

And 2 types differing by the principle of work:

- With closer - it works on opening and closes when the temperature in the greenhouse reaches above 30 ° C,

- Without a closer - it only works on opening.

Benefits of using the device

Device manufacturers guarantee the reliability of the thermal drive. High-quality models work smoothly and provide timely ventilation in the greenhouse.

Proper installation and operation can significantly increase the life of the thermal drive. The device does not need additional adjustment. The finished thermal actuator includes all the elements necessary for installation. Installation of the device does not require the participation of specialists.

Features of installing a thermal actuator

In the process of installing the device, it is important to consider that the mechanism is designed for a certain pushing force due to which it has a limited stroke, therefore it cannot be overloaded. When designing a ventilation system, it is recommended to install several small windows or windows instead of massive frames. It is also important to consider the type of crops that you plan to grow, as for tomatoes, drafts are needed to prevent late blight, but in such conditions it will be difficult to get a good crop of cucumbers.

It is worth remembering - when the device is triggered, its forced closure is unacceptable. When choosing a thermal actuator, it is necessary to take into account the load on the device, as well as the opening distance of the mechanism. Before buying, read the recommendations for operating the thermal actuator. Some models require dismantling for the winter.

Electric mechanism of action

In such devices, the mechanism is driven by a special electric motor. The command to turn on is given by the controller, which, in turn, starts working based on information from the temperature sensor.

The main advantages of these devices include high power and the ability to create programmable intelligent systems that include various sensors that can more accurately determine the temperature of ventilation in the greenhouse. Of the shortcomings of such a thermal drive, it is worth noting - the dependence of power supply and the high cost for an ordinary gardener. Also, the device cannot be used for a long time in conditions of high humidity.

Bimetal Thermal Actuators

In bimetallic thermal drives, the principle of operation is based on the coefficients of thermal expansion due to the use of different metals. Two plates are fastened together and when heated, one of them increases in size, due to which the window opens.

The main advantage of this type of device is simplicity and autonomy, with regard to the shortcomings - low power, due to which this model can only be used to open the window leaves.

Pneumatic devices

The mechanism of action of pneumatic thermal actuators is based on the supply of heated air to the drive piston from a sealed container. When the container is heated, the expanded air is supplied through the pipe to the piston, due to which it helps to open the window or door. In the event of a drop in temperature, the air is compressed and the piston returns to its original position, closing the window. A model that is quite common on the market along with hydraulic machines for ventilating greenhouses.

Hydraulic ventilation machines

The hydraulic thermal actuator starts working due to movement, by changing the balance in the weight of a pair of containers between which the fluid moves. In this case, the liquid begins to move between the vessels, as a result of which, the air pressure changes with a decrease or increase in temperature. The main advantage of this device is high power and full non-volatility.

Thermal drive "Bumblebee" from the company Kinplast

The Bumblebee thermal actuator is a unique development of the Kinplast company. The presented automatic machine for airing greenhouses and greenhouses has no analogues. The mechanism of action of the device is based on hydraulics. There is a liquid inside the thermal actuator, which expands as the temperature rises, due to which the door or window opens. The machine performs a smooth opening and closing if the temperature starts to drop.

The versatility of the product gives the presence of a volumetric reservoir in which there is a special liquid. The device is capable of opening and closing window panes or greenhouses made of cellular polycarbonate with a weight of up to 15 kg. The mechanism comes into action at 16 ° C - the gradual opening of the window starts, at 32 ° C - closing. The stroke of the stem is 90 mm, due to which the window opens up to an angle of 85 °.

The Bumblebee thermal actuator is a reliable device for providing an optimal microclimate inside the greenhouse. The case is made of stainless steel, so the mechanism easily withstands excess pressure at an air temperature of no higher than 50 ° C °. The thermal drive does not require the assistance of specialists in the installation, installation is easily carried out according to the instructions attached to the product.

Principle of operation

The thermal actuator responds to changes in temperature in the greenhouse. The device opens doors, windows, windows when the temperature rises above a certain value. There is additional ventilation of the room, as a result of which the temperature regime is normalized. In this case, the actuator of the thermal actuator returns to its original state with the onset of cooling.

According to the methods of operation that drive the thermal drive mechanism, the following are distinguished, differing in physical principles.

- Electric thermal actuator. The main elements of this device are an electronic control unit (controller), temperature sensors and fans. Information from temperature sensors is analyzed by the controller and the program selects the most rational mode of operation of ventilation units. The efficiency of the electric thermal actuator does not depend on the size and type of construction of greenhouses. The greenhouse quickly adjusts the desired temperature. However, the need for power supply limits its applicability, especially in suburban areas remote from cities.

- Thermal actuator based on the linear expansion difference of metals. Such a system consists of a bimetallic plate in which metals with a different coefficient of linear expansion are collected. When heated, such a plate bends and puts pressure on the actuator, opening, for example, a window. Independence from external factors (power supply), ease of installation and low cost of operation are the main advantages of this system. The disadvantages are the transfer of large amounts of heat to ensure operability (thermal inertia), low power and difficult selection of materials that work well in a given temperature range.

- Thermal actuator based on the principles of hydraulics and pneumatics. The difference between them is in the state of the working fluid - liquid or air.

At a certain temperature, for example, about 22 °, a special liquid begins to expand greatly and push with force the rod connected to the window, window or door. When the temperature drops back, the stem returns with a return spring. Along with independence from a power source, another advantage of such a thermal drive is the ease of installation and the ability to work with massive elements of the greenhouse design. The high cost and slow closing with a sharp drop in temperature limit its use for small greenhouses.

Design differences

The most common option in practice is one where a fluid is used as a working fluid, which begins to expand strongly in volume at temperatures above 23 ° C. The device kit includes, in addition to the thermal drive, all the necessary elements for its installation:

- thermal drive assembly with an actuator,

- closer - a lever system that provides opening / closing of a door, window leaf, window, frame of a greenhouse,

- a spring (there may be several), as part of a closer, creating a condition for smooth opening and using its elastic energy to close,

- brackets for attaching to the frame of the greenhouse and the body of the object opened by the thermal drive (windows, vents, doors and other types),

- clamps for mounting the ball bearings of the brackets to the ends of the thermal actuator and the spring,

- fasteners, for example, self-tapping screws.

In expensive versions of thermal actuators, gas springs are used instead of conventional springs, providing a more dense and smooth closing.

Thermal Drive Installation

The installation sequence is as follows.

- The thermal actuator should be mounted in a cooled state, so that the output length of the working rod is minimal. It can be put for some time in the refrigerator (not in the freezer!).

- Check how the door, window or frame closes freely. If there is any interference, they should be removed. If necessary, grease the hinges.

- Next, mark the places where the brackets will be installed. It is important to find suitable places on the opening leaf and on the fixed frame of the greenhouse. Attaching the bracket to the sash should ensure the full stroke of the thermal actuator stem.

- Having fixed the bracket on the opening part, you should mark the mounting points of the brackets on a fixed frame. It is important to ensure maximum opening of the sash in accordance with the largest length of the retractable stem of the thermal actuator.

- Put on the ends of the spring and the thermal actuator.

- Connect the clips to the ball bearings on the brackets. Fixation should begin with the brackets located on the fixed part of the frame, and end with fixation on the movable sash.

- After testing, the thermal actuator is ready for operation.

Design features of some types of thermal actuator can make changes in the sequence of actions during installation.

Criteria for choosing ventilation machines for greenhouses and greenhouses

Often, considerable finances spent on an expensive thermal drive disappear in vain: the device refuses to work due to large deformations in the structure, it cannot be installed on the frame of the greenhouse, and a normally working thermal drive does not withstand temperature and humidity for plants planted in the greenhouse. As a result, yield loss, not fruit ripening on time.

Methods of organizing ventilation with the help of automatic ventilation systems differ from the types of crops grown in the greenhouse. So, for example, agricultural technology for growing tomatoes is different from the technology for cultivating cucumbers. For the growth of tomatoes, a dry climate at a given temperature is important. Cucumbers love a humid climate without excess heat.

In terms of this, ventilation methods are distinguished - for tomatoes, ventilation is carried out by direct flow by opening the doors, and for cucumbers, the air moves from above from open air vents and transoms to maintain moisture in the lower layer near the soil.

After determining the number of thermal actuators installed on the door or vents, they proceed to the selection of models having design features depending on the installation location. There are thermal drives that can only be installed on the windows. More universal and accordingly expensive can be equipped with all opening greenhouse construction elements.

The main parameter for choosing a ventilation machine is its opening force. A high value of this parameter will guarantee increased resistance to additional wind load, to worn hinges on doors and windows.

You can use the following recommendations for choosing a thermal actuator for the opening force:

- when the greenhouse is located in a section closed from the winds, when using doors and window leaves weighing no more than 3 kg, an automatic machine is sufficient for ventilation with an opening force of up to 7 kg,

- if the greenhouse is located in the zone of moderate wind activity (up to 8 m / s), then for standard sizes of window leaves and doors, an opening force of 20 kg to 30 kg is sufficient,

- at high wind loads (from 8 m / s to 13 m / s), depending on the size of the window leaves and the weight characteristics of the doors, the force to open the thermal drives will need from 30 kg to 100 kg.

Parameters of thermal actuator models in comparison

Numerous shops selling this product in Moscow and other Russian cities offer a wide range of automatic ventilation machines for greenhouses both domestic and foreign. It is almost impossible to determine the manufacturer among a large number of Chinese goods, which can be under any brand of a well-known company. Therefore, specifications apply only to model names.

Comfort AERO Model

| Force area | door, any window |

| Magnitude of the developed effort | 100 kg |

| Operating temperature range | from -50 ° С to + 60 ° С |

| Winter conditions | winter shooting is not required |

| Rod travel length | maximum 90 mm |

| Start temperature | |

| at the opening | 23 ° C |

| to close | 22 ° C |

Model "Vent - L 001"

| Force area | door, any window |

| Magnitude of the developed effort | 100 kg |

| Operating temperature range | from –40 ° С to + 60 ° С |

| Winter conditions | winter shooting is not required (at T 60 ° С |

| Winter conditions | no reliable information |

| Rod travel length | 30 mm |

| Start temperature | 17 ° С – 25 ° С, adjustable |

Model TP - 440

| Force area | lift window |

| Magnitude of the developed effort | 7 kg |

| Operating temperature range | from –50 ° С to + 60 ° С |

| Winter conditions | winter shooting is not required |

| Rod travel length | 900 mm maximum |

| Start temperature | 23 ° C |

Model "Dusya San"

| Force area | lift window |

| Magnitude of the developed effort | up to 7 kg |

| Operating temperature range | from 0 ° С to + 50 ° С |

| Winter conditions | not used in winter |

| Rod travel length | 100 mm |

| Start temperature | 15 ° С – 25 ° С |

Model "UFOPAR"

| Force area | door opening |

| Magnitude of the developed effort | 100 kg |

| Operating temperature range | from –40 ° С to + 60 ° С |

| Winter conditions | winter shooting is not required |

| Rod travel length | 70 mm (angle 90 °) |

| Start temperature | 16 ° С – 25 ° С |

Recommendations for ensuring long, trouble-free operation of the thermal drive

- Install the thermal actuator in strict accordance with the instructions attached to the technical documentation for the operation of the device.

- When operating the thermal drive in climatic conditions with difficult wind conditions, measures should be taken from the destruction of the device by the wind. It is necessary to equip the opening sash with a restrictive cable, making it impossible to open it maximum more than the total extension of the working rod of the ventilation machine.

- The opening force should be commensurate with the weight and overall characteristics of the window, window, door. With effort, for example, a kilogram window will hang even with a slight wind. All hinged joints of the structure will quickly break, and during cooling such a window will not provide tight closure from the penetration of cold air into the greenhouse. A heavily loaded window will reduce the service life of the automatic ventilator.

- The details of the design of the thermal actuator are made of materials with corrosion resistance (stainless steel, aluminum alloys and others) or coated with, for example, zinc or chrome (vent rod). The chromed stem can be protected against dripping condensate by a lower position relative to the opening leaf. Condensate will drain freely without encountering obstacles in its path.

DIY manufacturing methods for a thermal actuator

Many owners of greenhouse structures, wanting to save on maintenance and get a decent harvest, provide automatic opening of window leaves in the greenhouse with their own hands. It is important for users who want to install a thermal drive on their own that the reliability of this device must be very high. The slightest failure can lead to a violation of the microclimate inside the greenhouse. This can disrupt the biological development of plants, and in some cases cause their death.

Variants of the emergence of new ideas are not excluded, but in this case it is better to be based on tried and tested constructive solutions.

Thermal actuator from automobile gas shock absorber

For the manufacture of a device for ventilating a greenhouse, the following materials and tools will be required:

- gas shock absorber from a car,

- a copper tube with a high pressure nipple at one end,

- powder fire extinguisher oil receiver,

- oil drain valve,

- electric drill,

- a soldering iron with all the materials for performing soldering technology,

- tension / compression spring,

- set of bench tools.

The sequence (approximate) of the work in the following description.

- On the body of the shock absorber, a place is chosen for opening the hole and lowering through it the gas mixture contained inside. The best option would be to keep the hinge in the design of the shock absorber in order to carry out this technological operation directly through its shaft. The hinge can then be used to secure one of the ends of the spring.

- To obtain a quality hole, into which a copper tube will then be inserted, it is necessary to prepare a surface that is perpendicular to the axis of the drill. This operation can be performed with a bench file.

- Important: when drilling, it is imperative to wear glasses, as the resulting chips can throw excess pressure into the face of the gas in the shock absorber.

- After venting the gas, the shock absorber should be flushed with hydraulic oil (it will continue to play the role of a working fluid). This operation will protect the mechanism from possible ingress of chips and as a result of wear on the shock absorber piston.

- Before brazing the surface of the copper tube and the brazing zone of the shock absorber, peel, degrease, and tin. Soldering is best done with a soft solder that does not require heating to high temperatures. This will reduce the risk of shock absorber cylinder deformation.

- After soldering a copper tube to the shock absorber, the receiver should be modified, for example, an oil receiver from a powder fire extinguisher. In its lower part, make a threaded hole to equip a crane for draining / filling oil and to control the presence of air in the system. If necessary, modify the coupling of the nipple of the copper tube (align the length of the threaded part with the nipple).

- Assemble a self-made thermal actuator, retrofit with a return spring, fill the tank with hydraulic oil, completely displacing the air in it. Before operating in the greenhouse, conduct test tests on how the stem movement responds to temperature changes.

Plastic Bottle Opener

The simplest version of the most common improvised materials can be used to open small windows of compact greenhouse devices.

The following materials will be required:

- 5 liter plastic bottle

- 1 liter plastic bottle

- PVC flexible tube

- two connecting branch pipes,

- movable lever made of light material, such as wood,

- a spring, one end of which is mounted on a movable lever, the other on a fixed frame of the greenhouse.

- glue - sealant,

- black plastic wrap.

To manufacture a thermal actuator from the above materials, it is recommended to perform the following steps.

- Seal a large plastic bottle with a lid fitted with non-adhesive sealant. Make a hole in the bottom of the bottle by making a connection with the nozzle through it, putting it on the glue. A functioning device will only be guaranteed that outside air does not enter the bottles.

- Do the same with a small plastic bottle. Connect the bottles with a PVC pipe tightly mounted on the nozzles.

- To increase the effect of absorption of sunlight, a large bottle should be wrapped in a black film.

- Cover the small plastic bottle with the movable lever. Under the action of the spring, the plastic of the bottle will collapse and in the initial state the window will be closed.

- as the temperature rises, the air in the large bottle will expand and fill the volume of the small plastic bottle. Under his influence, she will begin to restore shape, while raising the movable lever. The window will open, which will provide air exchange in the greenhouse. When the temperature drops, the spring will return the lever to its original state, again wrinkling the bottle.

Thermal drive from a metal container and a rubber ball (ball)

The manufacture of the mechanism will require the following materials:

- use metal cylinders or airtight cans as an air accumulator (preferably made of aluminum having good heat-conducting properties),

- a piece of polycarbonate remaining after the installation of the greenhouse,

- rubber ball or ball

- a piece of flexible durable hose that does not stretch under the influence of high pressure,

- a piece of thick stiff wire,

- sheet foam, which is used in packaging,

- sheet metal

- thick fishing line

- adhesive tape, sealant.

A variant of the device from the above materials is presented in the diagram:

The air heated in the canister, expanding, fills the rubber ball, which, increasing in volume, sets in motion the piston and the entire lever system for raising the window leaf.

It should be noted the manufacturing features of some structural elements associated with the properties of the materials used. The cylinder is made by rolling into a roll of polycarbonate and fixing the cylindrical shape using tape. The use of polycarbonate is very helpful here. The low coefficient of friction virtually eliminates piston jamming.

The piston is a thick stiff wire with a tightly set circle of foam. The guide sleeve is also made of polystyrene, but with a small clearance for free piston stroke.

The leverage system consists of a rocker arm made of sheet metal, which is connected to the window with a thick, durable fishing line.

The above designs cover only part of the options for how to make your own device for automatically opening windows in a greenhouse. In addition to them, gas lift from the office chair, trunk stops from some car models, old machine hand pumps and other technical devices that the wizard’s imagination can turn into an automatic ventilator for greenhouses are used as basic elements for manufacturing a thermal drive.

Some of them require a more fundamental approach, for example, how to adapt the shock absorber to open the greenhouse automatically from the car. Other simpler ones, for example, based on plastic bottles, are designed for use over a short time period.

In large farms, where large greenhouse complexes are used, it is hardly possible to make a thermal drive with your own hands, which is called for all occasions. But summer residents for their small greenhouses and hotbeds as a saving mode can well do with homemade devices. Especially if the structure is made of polycarbonate. Light in weight, it does not require much effort to lift the window leaves made of it.

The need for ventilation: reasons

To grow a large number of quality products, gardeners and gardeners must provide the most comfortable conditions for their land. The work of the greenhouse is to maintain optimal conditions for the growth and development of vegetables. To do this, it performs the following functions:

- maintains a temperature that should be at least twenty-two degrees of heat,

- maintains optimal air humidity, which is unique to each type of plant,

- provides airing.

To carry out the process of normalizing such necessary indicators as temperature and humidity, plants must “take air baths”.

A few years ago, ventilation was carried out by opening windows and doors. But today there are devices for automatically opening and closing windows in greenhouses. The standard method of ventilation is not entirely suitable for the normal functioning of plants. Since the draft is a sharp drop in temperature and humidity in the room, which can be detrimental to the culture.

In addition to the fact that auto-ventilation controls the necessary climatic parameters, it is able to prevent the penetration of harmful bacteria and fungi into the greenhouse. That is why, in order to save personal time and a normal microclimate, it is recommended to install thermal drives in greenhouses, they will provide high-quality ventilation, because every farmer knows that the presence of fresh air is the key to the rapid growth of plants.

Features and Benefits

The heat sink is an automatic closer that starts its work when the temperature of the air in the greenhouse rises, by opening the window. In other words, its principle of operation is based on the fact that the window opens when the temperature for crops is too high. The self-ventilator has such positive characteristics as:

- you don’t have to constantly monitor the temperature in the greenhouse,

- in order to function, the ventilator does not need to be connected to the mains,

- self-opening automatic equipment for windows can be purchased at any construction or gardening store, as well as made with your own hands.

Before buying a thermal actuator, do not ignore the feature of installing and using the ventilator. It is important to know that the force during opening and closing the window opening should not be more than five kilograms. The thermal drive consists of two elements, the first of which is attached to the wall of the greenhouse, and the second to the window or door. The features of the ventilator include the fact that the cavity inside it is filled with liquid. It is this moment that is decisive for the need to open or close a window. That is why it is not necessary to disassemble the auto-ventilator into separate elements, as this can harm its design. The device functions fully only if it has the required amount of fluid.

Important! An advantage of this device is also the fact that it can be used both in a greenhouse made of polycarbonate and in a greenhouse "dome" of another material and shape.

Characteristics and principle of operation

Whatever type of thermal actuator is used, its main task is to properly ventilate the room while increasing the maximum allowable temperature threshold. If this indicator decreases to the optimal norm, the controller closes the door and window. A temperature drive is a device consisting of two parts such as:

- temperature sensor,

- the mechanism that drives this device.

These components can be positioned and designed in different ways.

The auto vent can also be supplemented with a door closer and a lock, which are responsible for the density of closing the holes during self-ventilation.

There are several types of automatic ventilation machines for greenhouses, which differ in the mechanism of operation.

- Volatile. This electric drive drives the motor. The function of turning on the device is carried out by the controller, he is able to quickly respond to the temperature sensor. The advantages of this thermal actuator include programming its parameters at the discretion of the user. As a disadvantage, we can distinguish its dependence on electricity, with which failures often occur.

- Bimetallic. His device includes several metal plates that are interconnected. Each component is characterized by a reaction to a change in air temperature. The dimensions of the first increase, while the second, on the contrary, decreases. This feature makes it possible to easily open the window to carry out ventilation and in the reverse order. This system is simple and autonomous, but at the same time it has the disadvantage of a low power for opening and closing.

- Pneumatic. Nowadays, this species is considered the most common. The basis of his work is the supply of heated air to the piston system.From a sealed heated container, air is sent to a piston drive, which is mounted to drive the entire mechanism. The disadvantages of the device include only the fact that it is quite difficult to do it yourself.

- Hydraulic. It has a simple design and is therefore often used in recent years. Its basis is two communicating vessels. The liquid from the first to the second is transmitted when the air pressure changes, when it is heated and cooled. The positive characteristics of the device include its good power, non-volatility and ease of assembly. No flaws were noticed.

Thermal actuators have the following positive characteristics:

- reliability - thanks to the high-quality materials of which the device is made, the auto-openers withstand enormous pressure, the products are quite durable, as well as resistant to strong winds and an accidental attempt to manually close the door,

- long service life

- lack of need for adjustment,

- universality of use,

- the ability to install without professional skills.

Many people think that the independent manufacture of a thermal actuator is an impossible task. But this is not quite the right opinion, since in practice everything looks much simpler than it seemed. To complete the work it is necessary to spend time, effort, and also apply the appropriate knowledge.

Do-it-yourself self-ventilation can be made in several ways.

From a cylinder from a computer chair

Using objects at hand to create something useful is interesting, practical and effective. The main rules when working are consistency and clarity of execution. For the manufacture of a ventilation device, it is necessary to take a cylinder from a computer chair, on one side of it there is a rod made of steel, on the second - from plastic. The process includes the following steps:

- it is worth pulling the rod out of plastic,

- the cylinder needs to be relieved of pressure from the inside by putting a pin of metal on it,

- the cylinder is cut off by a grinder,

- it is necessary to carefully remove the stem from steel without damaging it,

- M8 thread is put on the rod for safety, and the part is clamped in a vice,

- from the internal parts of the cylinder, it will only be necessary to use a sleeve, which is put in place and a piston made of aluminum, from which rubberized rings are taken,

- each element should be cleaned by washing in gasoline,

- carefully insert the stem into the sleeve, the end of which should be outside,

- on the existing thread, it is necessary to tighten the nut, which is designed to hold the stem,

- then an aluminum stem is inserted,

- an elongated nut is put on the rod thread,

- the plug must be inserted and connected to the control levers,

- the system should be filled with engine oil.

Thus, the thermal drive will be ready to use and perform its immediate tasks.

DIY thermal drive for greenhouses

The main task when growing vegetables and herbs in a greenhouse is to create and maintain an optimal microclimate. In other words, a sufficient amount of fresh air should enter the room, but the temperature inside should not decrease.

Note: Some greenhouse owners simply open windows or doors to increase the flow of air entering. As a result, a draft is formed, which negatively affects the condition of the plants and can even cause the death of especially capricious specimens.

Accordingly, the task of the owner of the greenhouse is the timely opening and closing of the ventilation holes. This, in turn, requires a permanent presence on the site. But what about those who come to the country only on weekends and are not able to control ventilation? It is in this case that the thermal drive is useful - a compact device that works in automatic mode, opening and closing the air vents if necessary.

Types and design features

Thermal drives for industrial greenhouses look about the same. Homemade devices are quite another matter, for the manufacture of which folk craftsmen adapted the most diverse improvised materials.

Since it is not difficult to buy and install a finished thermal drive, we will consider the main types of home-made structures:

- From gas shock absorber: in this case, automobile oil is used as a working fluid. For the manufacture you will need a shock absorber piston, two cranes and a metal pipe in which the oil will be. The shock absorber rod is attached to the window. A crane is placed on one side of the pipe to fill the oil, and on the other, the same valve through which the oil will drain. The bottom of the gas spring is cut off and tightly attached to the pipe. By attaching such a device to the window, you will be sure that the ventilation will be carried out on time: the oil, expanding, will raise the rod and return it to its original position when cooling.

- From a plastic bottle: This budget option is great for small greenhouses that open with only a few windows. For the manufacture you will need two plastic bottles (5 and 1 liter), a little black plastic film, a piece of wooden board, two pipes and a meter tube of small diameter PVC. A hole is drilled in the center of the bottom of a clean and dry five-liter bottle. A pipe is inserted into it and connected to a PVC pipe. In order for the container to be completely tight, it is better to cover all joints with thermal grease. The remainder of the tube going from the bottom is inserted into a liter bottle. It is better to do this through a hole drilled in the roof. Next, you need to wrap a large container with black film and hang it under the ceiling. A small bottle is hung next to the window leaf. A wooden board is nailed to the transom with one edge, and the second is placed above the liter bottle so that it wrinkles. As a result of heating a large capacity, warm air will begin to flow into a small bottle. Under the action of expanded oxygen, it will straighten and raise the board, which will push the frame out.

- From balloons and ball: Another simple type of home-made device for ventilating the greenhouse. To make it, you will need a small wooden box with a lid, a ball, a hose, a board and two cylinders. A hose is connected to the connecting cylinders, and its length must correspond to the height of the greenhouse. The second end of the hose is put on the nipple of the deflated ball. The ball must be put in the box and close the lid. We beat the board to the lid and connect it to the transom. Cylinders are suspended from the ceiling, and the box with the ball is installed under the window. Cylinders, warming up, will begin to supply warm air through a hose to the ball. He pout, open the lid, and a nailed board will open the window.

All these types of home-made devices for the greenhouse are quite simple to manufacture, but do not forget that they do not have a long service life, especially for bottle designs. Therefore, if you want to make a more reliable design, you will have to use more durable materials.

How to make a thermal drive yourself

There are a lot of options for manufacturing a homemade thermal actuator. Some of the simplest ones we have cited above. But, if your greenhouse is large, and you plan to use an automatic ventilation device for a long time, we offer you several other options for home-made thermal drives.

To make them, you will need more materials and time, but at the same time you will be sure that a home-made device will last without fail for a long time.

From an office chair and other materials

An old computer chair is a source of excellent raw materials for making a durable and reliable thermal drive to the greenhouse.

Note: In any office chair there is a special lifting cylinder (gas lift), with which you can adjust the landing height. It is this detail that we will use as the basis for a home-made device.

To make a thermal drive from an office chair, you will need the cylinder itself, a vise, a piece of metal pipe, a grinder, a welding machine, and machine oil (Figure 2).

Assembly is carried out as follows:

- The end of the plastic rod is clamped in a vise and pulled out. You should see the valve pin inside.

- Next, you need to clamp the metal axis in a vice (diameter 8 mm and height 6 cm). On this axis you need to lean the cylinder and bleed all the air from it.

- Grinder cut off the cylinder with a taper and squeeze the stem. At this stage, care must be taken not to accidentally damage the surface of the part and its cuff.

- On the stem, you need to cut the M8 thread and install the inner cylinder liner back. All components of the workpiece must be thoroughly rinsed so that no metal shavings remain on them.

- Insert the stem into the sleeve and carefully remove it from the cylinder so that the gland is not accidentally damaged during the process.

- A nut is screwed onto the stem so that during operation the stem does not fall into the cylinder. Next, you need to insert the aluminum piston inside, and to the outer end - tightly weld the pipe.

- At the final stage, an M8 nut is screwed onto the stem thread and connect the stem to the window with a fork.

Figure 2. Manufacturing technology of home-made thermal actuator

Figure 2. Manufacturing technology of home-made thermal actuatorNow all that remains is to install the structure in the chosen place and add engine oil to the system. When heated, the oil will actuate the stem, which will open the transom, and when cooled, the liquid will begin to compress, and the transom will close.

From shock absorber

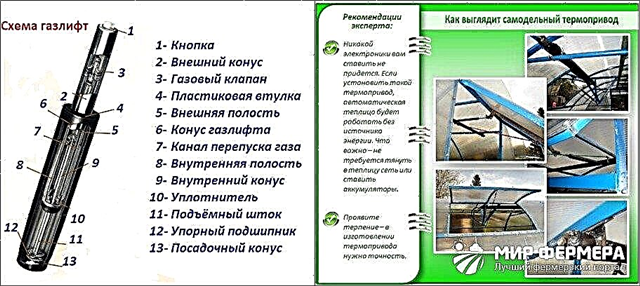

An ordinary automobile shock absorber can also be turned into a thermal drive for a greenhouse, but it should be borne in mind that this detail will need some refinement (Figure 3).

First, gas must be released from the shock absorber. For this, a hole is drilled in it, a thread is cut and a hose from the brake system is inserted into the hole. Next, you need to make a receiver for the drive. If you have metal working skills, you can make it yourself, or order a part from a turner according to ready-made drawings.

When all the parts are ready, you need to displace the air from the shock absorber and pour oil into it. It is important to ensure that the stem is completely submerged in the fluid. At the final stage, you just have to check the tightness of the system connections and install the device on the window.

Figure 3. Scheme of manufacturing a device from a shock absorber

Figure 3. Scheme of manufacturing a device from a shock absorber

It is better to install such a device under the ceiling, where the air heats up faster. Accordingly, the engine oil will begin to expand faster, actuate the stem and it will open the window.

Mounting a thermal actuator in a greenhouse

After you bought or made a thermal drive with your own hands, it remains only to install the device correctly. This process also requires certain knowledge, but we have prepared a step-by-step instruction for you, which will help you put it correctly in the greenhouse (Figure 4).

Installation of the device is carried out as follows:

- Check the ease of opening the window or door. For the appliance to work properly, the sash must open without much effort.

- On the sash, make a mark on the place of the future mechanism fastening. It is important to consider that the stock should move within 8-10 centimeters.

- Drill a hole and attach the bracket for the thermal actuator.

- Next, attach the spring to the frame, and the thermal drive to the wall of the greenhouse. Due to this, even when the sash is fully opened, the device will work correctly and will not begin to move.

- At the final stage, attach the device itself, and it is better to mount it either under the ceiling or on the wall opposite to the window that opens.

Figure 4. Device installation diagram

Figure 4. Device installation diagramWhen the installation is complete, you just have to check the correct operation of the device. It is important that none of the parts of the thermal actuator should rub against the walls or frame of the greenhouse.

If you bought a ready-made thermal actuator in the store, the task is simplified even more, since a drawing and installation instructions are necessarily provided with the device.

Detailed instructions for manufacturing a thermal drive from improvised materials are given in the video.