Putty plaster universal KNAUF-Fugen.

This site uses cookies to provide you with the best user experience. By continuing to browse the site you are agreeing to our use of cookies.

Privacy and cookie policy

When using the “Share” function on social networks, your personal data will be transferred to the appropriate service.

Activate Share

Putty joints. What is it for

After finishing the GKL room at the exit, smooth wall surfaces are obtained, except for places between the sheets. The thing is that GCR at the edges have a chamfer in the form of an oblique cut. And the result is small longitudinal recesses at the junction of the sheets.

For any further finishing, you will need to smooth out all the surface irregularities. Neither for painting, nor for wallpapering such irregularities are suitable, they simply spoil the appearance of the entire finish.

If you simply putty the space without additional reinforcement, then due to thermal deformations, the plaster will crack at the place where the sheets touch, and over time, these cracks will expand, nullifying all the invested repair efforts completely.

As a conclusion, to putty the space between the gypsum coatings, it is necessary and always to apply reinforcement. What materials are used in the process of such work?

Drywall Paper Tape

Drywall manufacturers usually produce related materials, such as putties, mesh for reinforcement, and, of course, paper strips for reinforcement. The paper strip is made by the same companies as the drywall - Knauf, Next Build and others.

On the shelves, the tape for the joints of drywall comes in the form of rolls with a length of 50 and 153 meters. This material is a strong, fiberglass reinforced paper. The adhesive side has rough edges to provide better adhesion. To ensure convenient gluing of the inner corners, there is a crease in the middle of the paper strip. The material withstands stretching and crushing.

But as with any material, paper material has its drawbacks. A strip of paper is inconvenient to use in the absence of experience, air bubbles may form when glued. To avoid this problem, it is best to buy a perforated strip. Small holes do not reduce paper strength, and air bubble problems can be avoided.

Serpyanka

Serpyanka is called a grid, which is produced in the form of a strip with a width of 45 and 50 millimeters. To stick it, special compositions are not required, it has its own adhesive part. There is also a cheaper serpyanka - without glue, which is fixed with a construction stapler.

The drywall net is made of fiberglass and has a huge margin of tensile strength. The length of the roll is from 20 meters, but it can be 45 and 90 meters.

If a self-adhesive serpyanka is used for sealing, then after completion of work it must be packed in a plastic bag, otherwise the glue will dry out over time and its further use will be impossible.

So which is better: a sickle or paper tape? It's all about their application. The mesh is not used at transverse seams, as it will not provide sufficient reinforcement. A paper strip, on the contrary, is not recommended for use on longitudinal seams between gypsum plaster.

Use of a sickle

Sealing between the sheets is carried out before the start of plastering. Most often, fiberglass mesh is mounted on longitudinal seams. The technology for using serpyanka is as follows:

- The starting gypsum mixture is being prepared. Using a plaster spatula (40 - 50 mm), put a thin layer of putty.

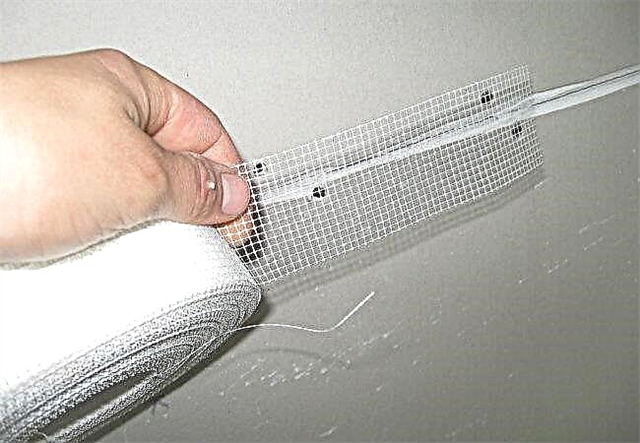

- Immediately, without a pause, the edge of the mesh roll is fixed to the top of the seam. Lightly melt into the plaster mixture.

- Unwinding the roll from top to bottom, the sickle is glued along the sheets and pressed into the putty using a spatula.

- When they reach the bottom edge, they cut the grid.

- On top of the grid once again pass with a spatula, smoothing the folds.

- Serpyanka on top is once again covered with a thin layer of starting plaster and left to dry.

Do not put too much pressure on the spatula, as this will create mesh folds, as well as reinforced drywall tape can be damaged by the edge of the tool.

You can also mount the sickle dry. To do this, use an adhesive or regular mesh. Unwinding the roll, the material is simply glued to the surface. In the absence of self-gluing, a sickle is fixed along the entire length with stapler clips. Top cover with a layer of plaster mixture and smooth.

Using paper tape

A paper strip is best used for sealing transverse joints. In such places, it provides greater strength than a sickle. Knauf tape for GKL seams has proven itself best in finishing work. On the transverse seam, it forms a very strong plane, which will avoid the appearance of cracks in the future. The difference from the serpyanka is the installation technology. Knauf paper tape for GKL joints in use has its own nuances.

- The main difference is that the paper tape for drywall does not have a self-adhesive surface, its use involves the use of an additional adhesive. For its installation on sheet joints, a thin layer (1 - 2 mm) of the stucco mixture is preliminarily applied.

- Next, drywall paper is laid on the surface from one edge to the other.

- After gluing, the strip is slightly pressed into the putty layer.

- To prevent the occurrence of air pockets, the tape for sealing GKL joints is smoothed with a plaster spatula from the middle to the edges.

When gluing a paper strip, you do not need to immediately putty on all the seams. The drying speed of modern gypsum plaster is within 30 minutes, and a thin ball will dry even faster. Therefore, the incorporation of paper is carried out, gradually moving from one seam to another one by one.

Also, when smoothing strips along the edges, an excess of putty mixture will come out, it is carefully removed with an edge with a spatula immediately until it dries. If this process is left for later, it will be very difficult to remove dried plaster.

After gluing the places between the gypsum plaster, the surface is finished according to the usual method with stucco mixtures using a reinforcing mesh. An area aligned in this way will be suitable for use with any of the selected finishing materials.

The sealing of the joints of the sheets is an obligatory step in the further finishing of the surfaces of the GKL room with plaster mixes. The technology itself is quite simple and does not require special tools. The used mesh or paper tape for Knauf drywall will significantly strengthen the space between the sheets and prevent the occurrence of cracks in the future.

Paper tape

Builders note the high quality of several manufacturers: NextBuild, Sheetrock, Knauf. The last manufacturer has established itself on the reliable side, producing quality products. For its production, a particularly durable grade of paper is used, which is additionally reinforced with fiberglass across and along the canvas. To putty better adhere to the surface of the tape, it was made a little rough.

Knauf paper tape

Knauf paper tape

Knauf tape is also used to seal the internal corners of the GKL structure, to prevent cracking and hardening of the structure. To facilitate the embedment process, manufacturers have provided a special indented fold in the middle of the strip.

It is distinguished by a natural combination, which corresponds to a reinforcing material, in our case cardboard, according to its technical and physical characteristics and properties. Among which are permeability, absorbency, coefficient of linear tension and others. This feature predetermines the reliability of the protection of the joints formed during the installation of gypsum plaster, from load and temperature deformations. Paper tape prevents the formation of microcracks in the joint cavity.

There are practically no shortcomings in the material, except that the complexity of the process and the formation of air bubbles, which is caused by an insufficient amount of putty.

With insufficient experience it is better to choose a material with microperforation. It will reduce the likelihood of air bubbles and will not affect the strength characteristics of the reinforcing tape for joints.

Knauf Tile Sealing Rules

Fiberglass mesh is an excellent material for sealing joints formed by sheets of gypsum board with a thinned edge. But its strength is not enough to close transversely seams. The risk of cracks in these places will reduce the paper tape. It forms a joint of extreme strength, regardless of the chosen putty. But the sealing of the seams will be of high quality only subject to certain subtleties of the work:

- Knauf without an adhesive base, therefore, a uniform thin layer of putty mortar is applied to the joint, which will serve as an adhesive,

Sealing with paper tape

Sealing with paper tape - The putty solution, especially the thinner layer, dries quickly enough, so do not put the putty on all joints at once. Otherwise, the workflow will be somewhat more complicated, and air bubbles may form,

- The tape is adjusted in the center of the seam. Holding it in a taut position, applying little effort, press it into the putty layer. Its ends when overlapping overlap,

- From the center to both sides of the seam with a spatula “stretch” the glued tape. In this case, a force is applied so that it is sufficient for reliable bonding, but so that an excess amount of putty is squeezed out. Under the edge should be approximately 0.8 mm, under the middle of the tape - 2 mm. If the putty is squeezed out too much, then the tape will not stick to anything,

- After the gluing and smoothing wrinkles are completed, they remove the excessive amount of putty mortar that has formed on the longitudinal edge,

- Then, after the putty material has completely dried, with a spatula with a wide blade, more than 100 mm, the seam is smoothed out completely. Attention is drawn to the fact that the layer of putty mixture on the GKL sheets forms a single plane. For the process, super-thin putty solutions from Knauf or Semin are used,

- The final step is grinding.

Self-adhesive reinforcing mesh

In construction, a sickle is used for sealing small holes, cracks, and processing joints formed by sheets of gypsum plaster with a thinned edge. High tensile strength is demonstrated by the products of many brands.

Bonding Serpianka on the seams

Bonding Serpianka on the seams

Serpyanka, in turn, is divided into non-adhesive and self-adhesive.

The first option is slightly cheaper, but the process of sealing joints is more time-consuming, as they are fastened with special paper clips. Using a self-adhesive serpyanka, the tightness of the package is monitored, otherwise the adhesive layer may dry out.

Sealing process using self-adhesive serpyanka

To reinforce the longitudinal joints formed by two sheets of gypsum plasterboard, a self-adhesive mesh is used. A lot less time is spent on the process of sealing with a sickle, since it is easier to use. The danger of air bubbles for the sickle is not terrible, they do not worry about this.

The disadvantages of using serpyanka include:

- Reduced strength compared to paper tape

- Selection of a suitable type of putty mortar.

Putting a plaster layer on top of a sickle

Putting a plaster layer on top of a sickleIf the joints are processed with a sickle, then experts recommend carefully applying it to all the seams of the room. Before applying the reinforcing mesh, the surface is dedusted, otherwise the formation of wrinkles cannot be avoided. Gluing a sickle, press it well against a wall or ceiling. After a layer of putty material is applied over the mesh and in its depth with a spatula. The putty layer should be uniform and thin.

The following video demonstrates all the subtleties and nuances of gluing paper tape:

What is it for?

Drywall - a material that is largely susceptible to fluctuations in temperature and humidity in the room. This is due to the fact that at the edges it has an unprotected chamfer. Particularly negative environmental conditions affect the joints of the ledger sheets. If a special tape for sealing joints is not used, then over time cracks will form on them, which can disrupt not only the appearance, but also the strength of the structure constructed from drywall.

The use of reinforcing products avoids these negative aspects, and also facilitates subsequent puttying and finishing. The use of the tape smooths out the bumps and roughness that are formed at the joints and makes the surface even, which allows for better quality subsequent painting of the material.

Why joints are putty

The joints are reinforced with reinforcing tape so that no cracks appear on the drywall surface. It will be unpleasant if, during the passage of the cold period, and the onset of summer, small cracks appear on the surface. If the wallpaper is pasted on top, this may not be noticed initially, but, after that, the wallpaper will begin to recede in the places of cracks. Then you have to redo all the work again.

The process of sealing a drywall seam with reinforced tape

The process of sealing a drywall seam with reinforced tape

The appearance of cracks arise from the temperature drop, and from the movement of the soil. It appears in a private home. The reinforcing tape for drywall serves as a fixing agent for the structure, it is extremely necessary in the plating of walls with drywall. There is a tape with metal inserts, which is designed to strengthen the corners of Knauf drywall. And also it is protection against damage to corners. This company differs from others in its quality, and accordingly in price: GKL - 260 rubles, reinforced tape - 150 rubles a roll.

How to glue a sickle

How to stick a grid on the seams? With abrasive paper, clean the place of the upcoming work. After grouting, be sure to blow off the seam to release dust and dirt.

Next, do this:

- Dry plasterboard with a special compound, expect to dry for at least a day,

- Chamfer if not done before,

- Knead the composition for putty, its consistency should be plastic,

- Apply putty, rub it into the gap between the sheets,

- Then a mesh is put on the seam, you need to glue it with an even layer,

- The net is wiped with a spatula so that it goes deep into the composition.

After the second layer, the tape needs to be leveled. After drying putty, wipe the place with sandpaper.

Varieties of tapes

Tape is an ideal material for reinforcing joints. It is easy to glue such a tape on GKL, but, nevertheless, some nuances of fastening must be observed.

Today, a wide selection of materials is provided to help seal the GKL joints. All of them are produced in rolls, forming a section of roll materials for GKL structures.

The following types of docking tapes are available:

- Serpyanka. The five-centimeter tape consists of synthetic fiber. Creates a strong putty coat.

- Fiberglass reinforcing tape. The width of this mesh tape can be either 10 cm or 23 cm. It creates high adhesion between itself and the material.

- Bandage or non-woven tape. Five centimeter width, fiberglass in the composition. Creates a reinforced corner.

- Perforated paper tape. One of the best types for GCR.

- Damper tape.It has a width of 3 to 10 cm and one side on an adhesive basis.

- Tape with a metal liner. Standard width - 5 cm, used to protect corners.

A smooth surface can be created with any of the following types. There are several types of docking strips for drywall

Laying a sickle

Most often, such a tape is glued to putty, but in some cases it can also be mounted on a dry surface.

With the first option, the algorithm of actions will be as follows:

- Putty is mixed. When buying, you should choose a special composition designed for processing drywall joints, for example, Knauf Uniflot. You need to prepare the mixture in small portions, this will allow you to use the material before it dries and deteriorates. The consistency of the finished solution resembles thick sour cream.

- The putty is pressed into the seam with a narrow spatula. A thin layer of it should also fall on drywall on both sides of the seam at a distance slightly greater than the width of the tape.

- Serpyanka is stacked from top to bottom, slightly recessed in a putty solution. If you have to fix several pieces, then their edges are overlapped. Excess cut with scissors.

- Use a spatula to heat the tape in the solution while smoothing it. Do not put too much pressure on the instrument: this way you can break the sickle. Or wrinkles may form. The mesh should be completely immersed in putty. Excess solution is removed at the same time.

- It is necessary to wait for the composition to dry. It will take 8-12 hours.

- Apply a thin finish to the mixture. Its main goal is to remove all minor flaws.

- After drying, the seam is sanded with fine sandpaper. At the next stage, the entire surface is primed and putty.

When dry-mounted, a self-adhesive serpyanka is pre-mounted on the joint, and then coated with putty solution.

The use of paper tape to seal joints on drywall

When creating drywall structures on the ceiling and walls, joints arise - the boundary of the connection of two sheets. The joint should be properly repaired, this serves as the strength of the entire structure. Paper drywall tape is one of many materials designed for such purposes.

And you should also choose a putty that will last a long time. It looks like a paper tape for sealing gypsum board seams. There are such materials on the market for sealing gypsum board seams: Sealing joints of drywall is simple, but important. Do not forget that the strength of the entire structure depends on this. Video on the sealing of drywall seams with paper tape. Knauf paper tape for drywall is a quality material: Paper tape for drywall joints is produced by many manufacturers, but the high quality of the Knauf brand is noted.

For the production of reinforcing tape, high quality raw materials are used, which are durable.

- It perfectly reinforces seams, creating structural strength.

- The tape does not tear after getting wet.

- It passes air well.

- It is not toxic to humans and animals.

The tape is pierced throughout the strip with fiberglass. The paper tape is a little rough to the touch. This is done for better adhesion to putty.

Kraft paper + PVA - it’s possible, as our drywall workers worked like that, everything is fine. Personally, I don’t like it because when installing GKL sheets on the profile between the sheets there are still gaps and the edge of the sheet should still expand, and all this uniflot fills well this way, and it keeps holding PVA and paper, but I still think and how these gaps are there. 2 Nail I agree, the option with a tape on PVA is considered by me for the case of very small gaps between the edges of the sheets. If the gap is large, then probably you should not leave a void under the putty.

- paper tape is thinner than a sickle. Due to this, the consumption of putty for the entire drywall is minimal,

- low cost

- ease of use. It’s no more difficult to glue a paper reinforcing tape than a sickle,

- good adhesion to putty. Perforated paper tape does not fall off during operation, and upon completion it tightly fastens the seams.

Putty is applied to the joint transversely to the seam line. After that, it is smoothed out with longitudinal movements, and then a reinforcing tape is laid on top. The sealing of drywall seams with paper tape is carried out using a wide spatula. With the same glue, a prepared joint of sheets of drywall is smeared. The cooked strip is superimposed on top - of course, it should be neatly smoothed.

After the glue dries, the tape will look as one with drywall. Such a seam can be processed with any material (paint, varnish, etc.). The resulting seam is filled with putty, and it must be smeared along the edges (a little more than the width of the tape). On the putty layer literally “the tape is pressed.

It should be well pressed and smoothed. After this, the seam should dry. Depending on the composition of the putty, the drying time can be up to 24 hours.

Additional information on the topic:

- How to mount drywall wall with niches

- How to build a drywall partition on profiles

- How to make a partition with a drywall arch video master class

- How to lay ceramic tiles on a drywall wall

- How to make a plumbing closet in a plasterboard toilet

Introduction

The technology of drywall works, without any compromises, involves the reinforcement of the joints of drywall sheets. This applies to the rules, both joints along the surface, and joints at the corners of structures.

The problem of reinforcing joints is solved in several ways, among which the more modern is the angle-forming tape perforated for drywall. It will be discussed in this article.

By the way, the use of special materials, like special services, to perform specific tasks, significantly improves the result. For example, high-quality cleaning in an office by a specialized cleaning company is much more effective than hiring a staff of cleaners. more details on the website of the company klining-for-business.ru St. Petersburg.

Knauf

This is a glueless paper tape with a width of 50 mm. It is made of special perforated paper having a very high coefficient of water absorption. Knauf tape is used more often if it processes joints of drywall sheets of the same company. The paper of this tape and the cardboard of Knauf boards can be called the most similar in physical and technological qualities.

If materials from one company are used, the likelihood of cracking and destruction of the putty layer is significantly reduced. Knauf paper tape for GKL joints is an adhesiveless tape 50 mm wide made of special perforated paper with a high coefficient of water absorption

Seam Docking

After installation, GKL structures are subject to subsequent finishing, part of which is the reinforcement of joints. The durability of the finish depends on the proper execution of these works.

In order to do everything correctly, it is necessary to choose the appropriate putty (the finish is enough if there are no obvious flaws and irregularities). The process of filling seams will not be difficult if you know it in detail and follow the rules, the main of which is accuracy.

The process of decorating is one of the most responsible and important, since the appearance of the structure as a whole will subsequently depend on the quality of the plastering.

Some flaws are removed with sandpaper after the putty dries, but this only applies to minor errors.

Types of sheet edges and types of joints

The transverse edge of all types of gypsum plaster is the same, but the longitudinal has some differences:

- Straight edge. Such ledger sheets are marked with a PC. As a rule, such a finish on the end of the plate is done on gypsum sheets intended for rough finishing, so the joints on them are rarely sealed.

- Semicircular edge (PLUK). On the back side of the sheets, the edge is straight, only the edge is rounded on the front side, such processing is most often found on GKL sheets. When sealing joints of sheets with a semicircular edge, as a rule, a sickle is used.

- Beveled edge (SK). It is found as often as semicircular. The seams between sheets with beveled rolling are closed in several stages and this process is quite laborious.

- Rounded edge (ZK). On the sheets GKL is less common. Sealing joints between a rounded edge is possible without the use of reinforcing tapes.

- Seam edge (FC). As a rule, it is found on gypsum fiber sheets (gypsum fiber), which are intended for rough finishing.

What causes cracks in drywall

Since drywall is a sheet material, it is obvious that the joints of individual sheets are potentially vulnerable places in any structure made of it. The load on them can become critical in cases of:

- The use of low-quality materials of the frame and the drywall itself.

- Violations of installation technology, in particular, if drywall is spread on several sides.

- Large changes in temperature and humidity.

The most common is the second case. Competent installation is a huge rarity, such is our people - does not like to read instructions and routings, but loves to save on building materials. Reinforcing tape for drywall will be of little use if you assembled a frame of shit and sticks, and even a sickle and even more so. In fact, a sickle is absolutely useless.

But if the installation of the structure was carried out efficiently, the reinforcing tape guarantees the absence of cracks, the experience of our masters confirms this. Hundreds of square meters of mounted claddings, partitions, ceilings, ducts - not a single crack.

It looks like drywall with putty joints

How to use tape

The tape goes well with polymer putty

Our turnkey solution is the use of gypsum plasterboard GYPROC and polymer putty Danogips SuperFinish (formerly Sheetrock APJC from USG). For factory joints, the technology is as follows. Without a primer (you can just wipe the dust with a cloth) putty is applied to the joint, excess is removed with a wide spatula. Then immediately the tape is laid in the joint and recessed into the putty with a narrow spatula

It is important not to overdo it, and under and above the tape putty should be. Superfinish polymer adheres well and is very durable

This technology is called “American”, because in North America, all joints are just sealed with paper and polymer. With KNAUF drywall, this method does not work because of their edges PLUK, they are very deep, and the polymer gives them a very strong shrinkage. In this case, you need to use gypsum Uniflot or Fugen.

This is how the cut edges of GKL look like

In the case of edged joints, the order is different. The seam must be expanded at an angle of 45 degrees and primed with deep penetration soil, then left alone for a day. After these days, it is filled with either Fugen or Uniflot, and it is filled with effort so that the putty adheres well to both sides of the sheet. Filling is done twice, as after the first putty will decrease in volume. We are waiting for complete drying, then apply the same Superfinish over a thin layer and glue our reinforcing tape on it (it can be pre-wetted to make it easier to slip), expel excess from under it and then apply the same thin layer on top of the tape.

After reinforcing the joints, our design becomes as if a single whole, and it is much more difficult to break a single whole than a set of parts, agree.

So, we threw the information for thought to you, now you like and subscribe

Perforated Corner Tape

The use of the phrase “forming an angle” in the name of the tape does not reduce, but, on the contrary, expands the purpose of this material. The formation of an angle in a building structure is only an option for its use. In addition, the perforated angle forming tape can strengthen the joints of sheets of any other sheet materials used in construction. For example, chipboard or fiberboard.

In addition, running on the tape - a marking line running in the middle of the tape, allows you to quickly form the corner of the structure or room. Perforation on the tape is needed for better interaction of the tape with the adhesive with the help of which the tape is fixed at the joints and corners.

It is worth noting that the perforated reinforcing tape is used by some finishers to form corners in concrete rooms without drywall. It is difficult to judge the effectiveness of this method, but this practice shows the expanded capabilities of this building material.

Squirrel tape

Serpyanka is a synthetic tape 5 cm wide of mesh. It is also called a construction bandage. When installing structures made of gypsum plaster, a five-millimeter gap is left at the joints. Serpyanka is glued in such a way that the gap is in the center of the tape, then putty is applied using a narrow spatula, which should fill the entire joint space. After the putty dries, you can apply the finish layer, creating a common surface of the joint and the material itself.

For a more durable connection of mounting slots between gypsum plasterboard structural elements using a sickle, you can use this method: the seam between the sheets is filled with putty, after drying, the protrusions are leveled and then the serpentine is glued. This method prevents the tape from getting inside the seam, and the connection is more durable.

The advantage of the sickle is that it is easy to stick. This increases the speed of work. In addition, it is quite durable.

Serpyanka is an adhesive reinforcing tape that serves to hold putty or plaster at the joints of two surfaces

Material setting

For Knauf drywall, it is better to choose embedments from the same manufacturer. For example, you can buy Knauf-kurt tape in rolls of 25 m. Or paper tape 52x150xS. The latter is made of special white paper, which includes reinforcing synthetic fibers.

Installation of paper tape is carried out in a certain sequence:

First you need to apply a thin layer of putty, but only on the joint that it was decided to close up at the moment. Putty can not be applied immediately to everything, otherwise the mixture will dry and become useless, and the work will be more difficult due to the possible occurrence of air bubbles.

The grid is regulated by two seams in the center. You need to keep it constantly tight. With a little effort, you need to pin the tape to the putty layer. The ends of the material must be overlapped.

Then it is necessary to smooth the tape with two spatulas, strictly following from the center to the sides of the seams

It is important to make enough effort so that the material adheres securely to the joint, and an excessive amount of solution extrudes outward. About 0.8 millimeters of the mixture should be under the edge of the paper, and about 2 millimeters under the center

It is important to note that if too much mixture is squeezed out, the tape will not be able to stick.

After the successful completion of all the manipulations, you need to remove the excess putty from the edges.

After some time, you need to finally smooth the seam with a spatula with a wide blade (more than 100 millimeters)

It is important that the seam does not go beyond the plane of the drywall.

At the end of the work, it is necessary to sand the layer well.

Installing a self-adhesive mesh requires much less time. This is due to the lack of risk of air bubbles. The process itself is also divided into several stages:

- Before starting the installation, you should prepare a putty mortar and apply it with a thin layer on the joint, using a spatula with a width of 40 to 50 millimeters.

- Then, without delay, you need to attach the edge of the grid to the upper edge of the seam and press it slightly onto the plaster. At the same time, you can not press hard. This can cause the appearance of “wrinkles” on the grid or lead to damage to the tape from strong mechanical stress.

- The roll should be unwound to the bottom, sticking the tape along the gypsum board and smoothing it with a spatula.

- At the floor, the net must be cut.

- Then you should again “walk” along the grid, smoothing the creases that have arisen.

- On top of the sickle you need to cover with another layer of plaster and leave to dry completely.

Self-adhesive serpentine can simply be fixed on a dry surface and covered with a thin layer of plaster on top.

Installation of the damper tape must be done slightly above the level of the floor screed. Typically, when laying gypsum plasterboard on the floor, builders leave a small gap of about 1 centimeter wide, into which they then lay the waterproofing tape and stick it in the gap between the wall and the floor. After that, the tape is filled with dry powder for installation.

Summarize

Numerous strength tests of reinforced joints have shown:

Joints reinforced with ordinary serpianka and finished with ordinary putty mortar are much more prone to cracking than joints reinforced with Knauf paper tape and putty mortar of the same company.

This is easily explained - a self-adhesive tape (serpyanka), even under a layer of putty material, is prone to stretching, which occurs under load. It is quite difficult to complete the overhaul of the formed cracks. Therefore, it is more advisable to use paper tape to seal the seams.

Plaster mortars company Knauf

Plaster mortars company Knauf

Tips from professionals

- When carrying out work to strengthen the joints between the GCR, it is necessary to take into account certain nuances.

- The heads of the screws should be recessed 1 mm in a sheet of drywall. Otherwise, the output will result in bumps that cannot be smoothed out.

- To avoid cracks, before reinforcing the joints, make sure that the drywall sheets are installed correctly and the metal frame is carefully fixed.

- If there is no chamfer at the joints, it must be applied independently, otherwise both the tape and the seam will burst after termination.

- In order not to form microcracks in the corners, it is necessary to fill them with putty very carefully and evenly.

- If a special tape is not used for corners, then the usual one must first be folded in half and then glued to the seam.

- It is important to read the information on the putty packaging or follow the recommendations of the manufacturer of the reinforcing tape. Some compounds are simply incompatible with the reinforcing tape and will not be able to keep it at the junction.

- When bubbles appear on a paper tape, they need to be pierced with a needle, and then carefully stick these places.

- If the GKL joint is very large in length, then the gluing of the reinforcing tape can be facilitated. To do this, it is cut into small pieces, usually no more than 1 m, and gluing is carried out in stages.

- Some gypsum board putty dries very quickly. You should consider this information and do not putty on the entire length of the seam immediately.

If all these tips are followed, as well as the manufacturer's recommendations, you can get high-quality GKL joints that do not crack and do not spoil the appearance.

How to choose?

Choosing the right type of Knauf tape depends on several criteria:

- Skill level. In the absence of experience, a serpentine should be preferred, and paper tape should be discarded, since it is more difficult to lay.

- For corners, it is better to use a paper tape, preferably corner forming.

- Do not use a sickle for joints that will be subject to significant mechanical stress, since this material has the ability to stretch, which negatively affects its reinforcing properties.

Tape for reinforcing the joints between the gypsum plasterboard is a necessary element, which, if used correctly, can increase the life of the structure to 10 years.

The main thing in working with the reinforcing tape Knauf is the strict adherence to the instructions and then you can safely hope for an excellent result and durability.

For information on how to properly lay the reinforcing tape, see the next video.